为物联网供电的高功率密度微型热电发生器

IF 5.3

2区 材料科学

Q2 MATERIALS SCIENCE, MULTIDISCIPLINARY

引用次数: 0

摘要

微型热电发电机(µTEG)可以利用废热发电,从而成为解决日益严重的自主电子设备(如物联网传感器)供电问题的潜在解决方案。到目前为止,µTEG 还不能为这些应用提供电力。这是因为 µTEG 的输出功率有限,原因是接触不足以及器件与热源之间的热耦合不良。在这项工作中,通过工艺优化,接触电阻以及热源与器件之间的热耦合都得到了改善。前者是通过改善电化学沉积 (ECD) 条件实现的,后者是通过引入薄焊料粘附层实现的。通过将这些改进与优化的堆积密度相结合,我们在此报告了具有 126 个串联脚对的µTEG 的制造和特性分析,该µTEG 在温差为 20.6 K 时的开路电压为 339.2 mV,归一化功率密度为 25.1 µW cm-2 K-2,创下了基于 ECD 的µTEG 的最高纪录。该 µTEG 用于为温度传感器供电,使这项工作离应用更近了一步。本文章由计算机程序翻译,如有差异,请以英文原文为准。

High Power Density Micro Thermoelectric Generators for Powering IoTs

Micro thermoelectric generators (µTEGs) can harvest waste heat to generate electricity, making them a potential solution to the growing problem of powering autonomous electronics, such as sensors for the Internet of Things. Until now, µTEGs have not been able to provide power for these applications. This is because the output power of µTEGs is limited due to insufficient contacts and poor thermal coupling between the device and the heat source. In this work, the contact resistance as well as the thermal coupling between the heat source and the device through process optimization are improved. The former by improved electrochemical deposition (ECD) conditions, the latter by introducing a thin solder adhesion layer, which smooths the uneven surface of µTEG due to its good wetting properties. Using these improvements in combination with optimized packing density, here the fabrication and characterization of a µTEG with 126 leg pairs connected in series are reported that exhibits an open circuit voltage of 339.2 mV at a temperature difference of 20.6 K and a record-high normalized power density of 25.1 µW cm−2 K−2 for ECD based µTEGs. This µTEG is used to power a temperature sensor, bringing this work one step closer to application.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

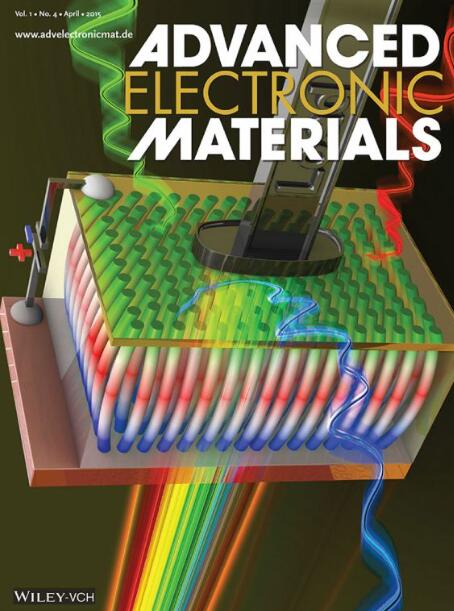

Advanced Electronic Materials

NANOSCIENCE & NANOTECHNOLOGYMATERIALS SCIE-MATERIALS SCIENCE, MULTIDISCIPLINARY

CiteScore

11.00

自引率

3.20%

发文量

433

期刊介绍:

Advanced Electronic Materials is an interdisciplinary forum for peer-reviewed, high-quality, high-impact research in the fields of materials science, physics, and engineering of electronic and magnetic materials. It includes research on physics and physical properties of electronic and magnetic materials, spintronics, electronics, device physics and engineering, micro- and nano-electromechanical systems, and organic electronics, in addition to fundamental research.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: