Effect of pre-freezing and accelerated thawing on frozen egg yolk gelation behavior revealing the molecular mechanism

Abstract

BACKGROUD

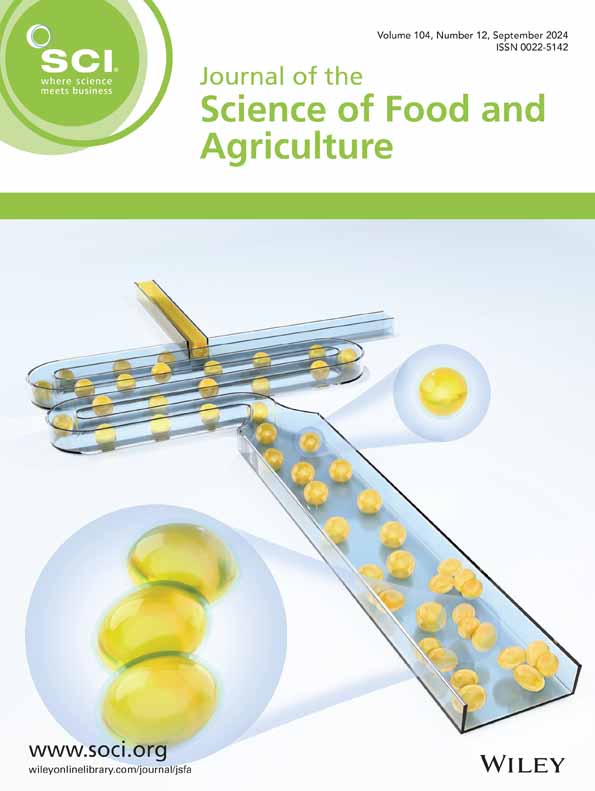

Freezing is a commonly used method to prolong the storage duration of egg yolk, which induces irreversible gelation after being stored below −6 °C. The present study examined the effects of pre-freezing and thawing conditions on the gelation of egg yolk liquid, accessing its rheological properties, molecular structure and water mobility.

RESULTS

The results indicated that pre-freezing at −40 °C for 7 days followed by storage at −18 °C was a cost-effective method, with the consistency coefficient being decreased by approximately 30% compared to that of egg yolk liquid frozen directly at −18 °C. Pre-freezing was beneficial in generating smaller ice crystals, preventing the protein denaturation and aggregation caused by mechanical damage from larger ice crystals, and reducing the loss of protein molecular bound water. On the other hand, thawing in a 50 °C water bath was found to be the most effective method. The consistency coefficient of egg yolk liquid pre-freezed at −40 °C for 3 days and then thawed at 50 °C decreased by 73% compared to the sample directly frozen at −18 °C and then thawed at room temperature. The increase in fluidity of egg yolk after freezing was related to protection of bonding water and less cross-linking, as verified by the higher content of β-sheet and smaller particle size.

CONCLUSION

The pre-freezing process promoted the formation of a greater number of small ice crystals, which mitigated the mechanical damage to proteins and the consequent denaturation and aggregation. Additionally, thawing at elevated temperatures could effectively avoid recrystallization, protecting proteins from denaturation and aggregation, leading to a further reduction in gel strength and an increase in fluidity. The findings of the present study contribute to a better understanding of the factors influencing egg yolk gelation and offer insights into the development of enhanced freezing and thawing techniques for egg yolk. © 2025 Society of Chemical Industry.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: