Improving the Collision Tolerance of High-Speed Industrial Robots via Impact-Aware Path Planning and Series Clutched Actuation

IF 9.4

1区 计算机科学

Q1 ROBOTICS

引用次数: 0

Abstract

Robots are more often deployed in unstructured or unpredictable environments. Particularly collisions at high speed can severely damage the drivetrains and joint bearings of robots. In order to avoid such collisions, path planners exist that adapt the robot's original trajectory online if a collision hazard is detected. These methods require additional sensors such as cameras, are computationally costly and never flawless due to occlusions. Another approach is to incorporate a cost function that promotes collision tolerance while planning the initial trajectory. The resulting impact-aware path plan minimizes the chance of robot hardware damage if a collision would occur. Two algorithms are presented to assess collision tolerance in high-speed robots, taking into account factors such as robot pose, impact direction, and maximum intermittent loading of the gearboxes and bearings. The first algorithm is more general while the second assumes the presence of joint overload clutches that decouple upon impact. These algorithms are applied to plan an impact-aware path for a custom 6-axis series clutched actuated robot that serves as use case. Both for the case with and without clutches, a generic impact-aware plan is presented as well as at least one derived, heuristic alternative. Without clutches, trajectories that are perpendicular to the end effector flange were found to be desirable, as they allow the robot to mitigate the highest collision force without overloading the gearboxes or bearings. On the other hand, with clutches, trajectories that are parallel to the end effector flange were found to be more collision tolerant. The effect of impact direction was also experimentally validated using the custom 6-axis robot. Collisions at velocities up to 1.2 m/s were mitigated through the combination of impact-aware path planning and series clutched actuation.通过冲击感知路径规划和串联离合器驱动提高高速工业机器人的碰撞耐受性

机器人经常被部署在非结构化或不可预测的环境中。特别是高速碰撞会严重损坏机器人的传动系统和关节轴承。为了避免这种碰撞,现有的路径规划器可在检测到碰撞危险时在线调整机器人的原始轨迹。这些方法需要额外的传感器(如摄像头),计算成本很高,而且由于遮挡物的存在,永远不会有缺陷。另一种方法是在规划初始轨迹时加入一个成本函数,以提高碰撞容忍度。如果发生碰撞,由此产生的碰撞感知路径规划可将机器人硬件损坏的几率降至最低。本文介绍了两种用于评估高速机器人碰撞容限的算法,其中考虑到了机器人姿势、撞击方向以及齿轮箱和轴承的最大间歇负载等因素。第一种算法更为通用,而第二种算法假定存在关节过载离合器,在撞击时会脱开。这些算法被应用于一个定制的 6 轴串联离合器驱动机器人的冲击感知路径规划,作为使用案例。在有离合器和无离合器的情况下,都提出了通用的冲击感知计划以及至少一种衍生的启发式替代方案。我们发现,在没有离合器的情况下,与末端效应器法兰垂直的轨迹是理想的,因为这样可以使机器人减轻最大的碰撞力,而不会使齿轮箱或轴承过载。另一方面,在使用离合器的情况下,与末端效应器凸缘平行的轨迹更能承受碰撞。我们还使用定制的 6 轴机器人对碰撞方向的影响进行了实验验证。通过将冲击感知路径规划与串联离合器驱动相结合,可减轻速度高达 1.2 米/秒时的碰撞。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

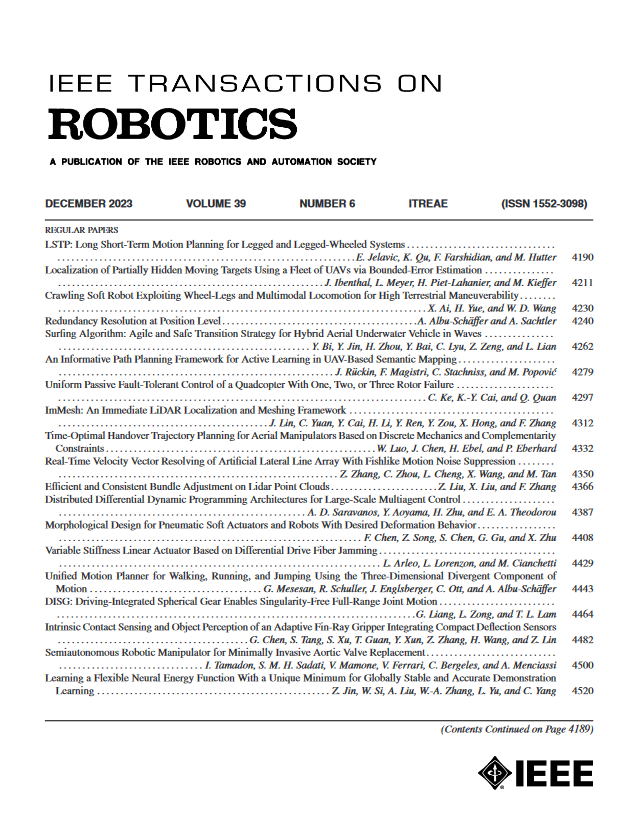

来源期刊

IEEE Transactions on Robotics

工程技术-机器人学

CiteScore

14.90

自引率

5.10%

发文量

259

审稿时长

6.0 months

期刊介绍:

The IEEE Transactions on Robotics (T-RO) is dedicated to publishing fundamental papers covering all facets of robotics, drawing on interdisciplinary approaches from computer science, control systems, electrical engineering, mathematics, mechanical engineering, and beyond. From industrial applications to service and personal assistants, surgical operations to space, underwater, and remote exploration, robots and intelligent machines play pivotal roles across various domains, including entertainment, safety, search and rescue, military applications, agriculture, and intelligent vehicles.

Special emphasis is placed on intelligent machines and systems designed for unstructured environments, where a significant portion of the environment remains unknown and beyond direct sensing or control.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: