具有剪切诱导排列碳纤维明确有序结构的3D打印铝基复合材料

IF 9.9

2区 材料科学

Q1 Engineering

引用次数: 3

摘要

采用3D打印方法制备了具有剪切诱导排列碳纤维有序结构的碳纤维增强铝复合材料。研究了印刷和烧结样品的微观结构以及复合材料的力学性能。碳纤维和铝粉用树脂粘合在一起。在3D打印过程中,通过剪切诱导排列将碳纤维的空间排列固定在铝基体中。结果,排列纤维平行排列的复合材料的伸长率和正交排列的复合物的冲击韧性分别为0.82%和0.41J/cm2,分别是随机排列的约0.4和0.8倍。本文章由计算机程序翻译,如有差异,请以英文原文为准。

3D printed aluminum matrix composites with well-defined ordered structures of shear-induced aligned carbon fibers

Carbon fiber reinforced aluminum composites with ordered architectures of shear-induced aligned carbon fibers were fabricated by 3D printing. The microstructures of the printed and sintered samples and mechanical properties of the composites were investigated. Carbon fibers and aluminum powder were bonded together with resin. The spatial arrangement of the carbon fibers was fixed in the aluminum matrix by shear-induced alignment in the 3D printing process. As a result, the elongation of the composites with a parallel arrangement of aligned fibers and the impact toughness of the composites with an orthogonal arrangement were 0.82% and 0.41 J/cm2, respectively, about 0.4 and 0.8 times higher than that of the random arrangement.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

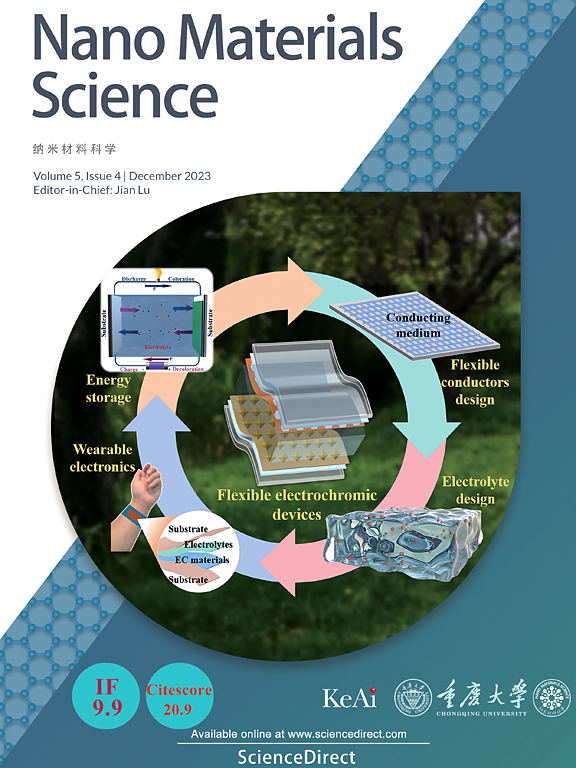

Nano Materials Science

Engineering-Mechanics of Materials

CiteScore

20.90

自引率

3.00%

发文量

294

审稿时长

9 weeks

期刊介绍:

Nano Materials Science (NMS) is an international and interdisciplinary, open access, scholarly journal. NMS publishes peer-reviewed original articles and reviews on nanoscale material science and nanometer devices, with topics encompassing preparation and processing; high-throughput characterization; material performance evaluation and application of material characteristics such as the microstructure and properties of one-dimensional, two-dimensional, and three-dimensional nanostructured and nanofunctional materials; design, preparation, and processing techniques; and performance evaluation technology and nanometer device applications.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: