通过构建层次化结构表面来提高导电CNT/PDMS复合薄膜的压力传感性能

IF 9.9

2区 材料科学

Q1 Engineering

引用次数: 0

摘要

柔性压力传感器因其在电子皮肤、健康监测、人机交互等领域的应用而受到广泛关注。然而,它们的高灵敏度和宽响应范围之间的权衡仍然是一个挑战。受人体皮肤的启发,我们选择商用碳化硅砂纸作为模板,通过溶液混合和叶片涂布,制备具有分层结构表面的碳纳米管(CNT)/聚二甲基硅氧烷(PDMS)复合膜(h-CNT/PDMS),然后将h-CNT/PDMS复合膜与交叉电极和聚氨酯透明胶带组装在一起,得到基于h-CNT/PDMS的柔性压力传感器。基于原位光学图像和有限元分析,与平面CNT/PDMS复合膜(0-240 kPa压力范围0.0066 kPa - 1)相比,h-CNT/PDMS分层结构表面与交叉电极之间存在显著的压缩接触效应,使得h-CNT/PDMS复合膜的压力敏感性增强,响应范围(0-18 kPa、18-133 kPa和133-300 kPa)分别为0.1661 kPa−1、0.4574 kPa−1和0.0989 kPa−1。所制备的压力传感器具有快速响应/恢复时间,优异的稳定性,耐用性和对不同加载模式(弯曲和扭转)的稳定响应。此外,我们的压力传感器可以用来准确地监测和区分各种刺激,从人体运动到压力大小和空间分布。该研究为下一代可穿戴电子器件中具有优异传感性能的柔性压力传感器的制造提供了重要的指导。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Advancing the pressure sensing performance of conductive CNT/PDMS composite film by constructing a hierarchical-structured surface

Flexible pressure sensors have attracted wide attention due to their applications to electronic skin, health monitoring, and human-machine interaction. However, the tradeoff between their high sensitivity and wide response range remains a challenge. Inspired by human skin, we select commercial silicon carbide sandpaper as a template to fabricate carbon nanotube (CNT)/polydimethylsiloxane (PDMS) composite film with a hierarchical structured surface (h-CNT/PDMS) through solution blending and blade coating and then assemble the h-CNT/PDMS composite film with interdigitated electrodes and polyurethane (PU) scotch tape to obtain an h-CNT/PDMS-based flexible pressure sensor. Based on in-situ optical images and finite element analysis, the significant compressive contact effect between the hierarchical structured surface of h-CNT/PDMS and the interdigitated electrode leads to enhanced pressure sensitivity and a wider response range (0.1661 kPa−1, 0.4574 kPa−1 and 0.0989 kPa−1 in the pressure range of 0–18 kPa, 18–133 kPa and 133–300 kPa) compared with planar CNT/PDMS composite film (0.0066 kPa−1 in the pressure range of 0–240 kPa). The prepared pressure sensor displays rapid response/recovery time, excellent stability, durability, and stable response to different loading modes (bending and torsion). In addition, our pressure sensor can be utilized to accurately monitor and discriminate various stimuli ranging from human motions to pressure magnitude and spatial distribution. This study supplies important guidance for the fabrication of flexible pressure sensors with superior sensing performance in next-generation wearable electronic devices.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

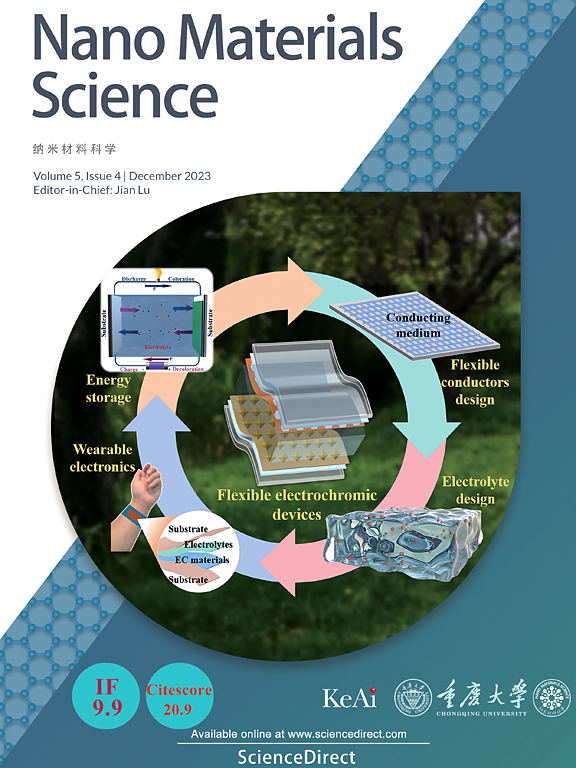

Nano Materials Science

Engineering-Mechanics of Materials

CiteScore

20.90

自引率

3.00%

发文量

294

审稿时长

9 weeks

期刊介绍:

Nano Materials Science (NMS) is an international and interdisciplinary, open access, scholarly journal. NMS publishes peer-reviewed original articles and reviews on nanoscale material science and nanometer devices, with topics encompassing preparation and processing; high-throughput characterization; material performance evaluation and application of material characteristics such as the microstructure and properties of one-dimensional, two-dimensional, and three-dimensional nanostructured and nanofunctional materials; design, preparation, and processing techniques; and performance evaluation technology and nanometer device applications.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: