固定化酶微反应器连续合成琥珀酸维生素E。

IF 3.9

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

摘要

琥珀酸维生素E作为一种高附加值产品,具有重要的抗肿瘤作用。然而,传统的琥珀酸维生素E合成方法往往受到高温、高压、反应时间长等原因的限制。这阻碍了它们在制药工业中的应用。本研究将脂肪酶CALB包埋的溶胶溶液包埋在微通道中,制备了一个壁包固定化酶微反应器,并通过该微反应器催化合成维生素E琥珀酸盐。通过响应面优化得到最佳合成条件:底物流速为25.33 μL/min,底物摩尔比为4.17,底物浓度为13.50 g/L,反应温度为52.41℃。此时琥珀酸维生素E得率可达65.10%。然后分别测定了微反应器和间歇式反应器中合成琥珀酸维生素E的动力学参数。结果表明:间歇式反应器中Km为265.3 mM,微反应器中Km为18.6 mM(流速为25 μL/min);进一步证明了在微通道中固定化脂肪酶可以充分结合微通道和酶催化的优点。有望为高效生产琥珀酸维生素E提供一条有潜力的新途径。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Continuous Synthesis of Vitamin E Succinate in an Immobilized Enzyme Microreactor.

As a high-value-added product, vitamin E succinate has an important effect in antitumor. However, the traditional synthesis methods of vitamin E succinate are often limited by high temperature, high pressure, long reaction time, and other reasons. This hinders their application in the pharmaceutical industry. In this study, a wall-coated immobilized enzyme microreactor was prepared by coating the sol solution embedded with lipase CALB into the microchannel, and the catalytic synthesis of vitamin E succinate was carried out through the microreactor. The optimum synthesis conditions were obtained by response surface optimization: a substrate flow rate of 25.33 μL/min, a substrate molar ratio of 4.17, a substrate concentration of 13.50 g/L, and a reaction temperature of 52.41 °C. At this time, the yield of vitamin E succinate can reach 65.10%. After that, the kinetic parameters of the synthesis of vitamin E succinate in the microreactor and the batch reactor were determined, respectively. The results showed that Km was 265.3 mM in the batch reactor and 18.6 mM in the microreactor (at a flow rate of 25 μL/min). It was further proven that the immobilization of lipase in the microchannel can fully combine the advantages of microchannel and enzyme catalysis. It is expected to provide a new and potential route for the efficient production of vitamin E succinate.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

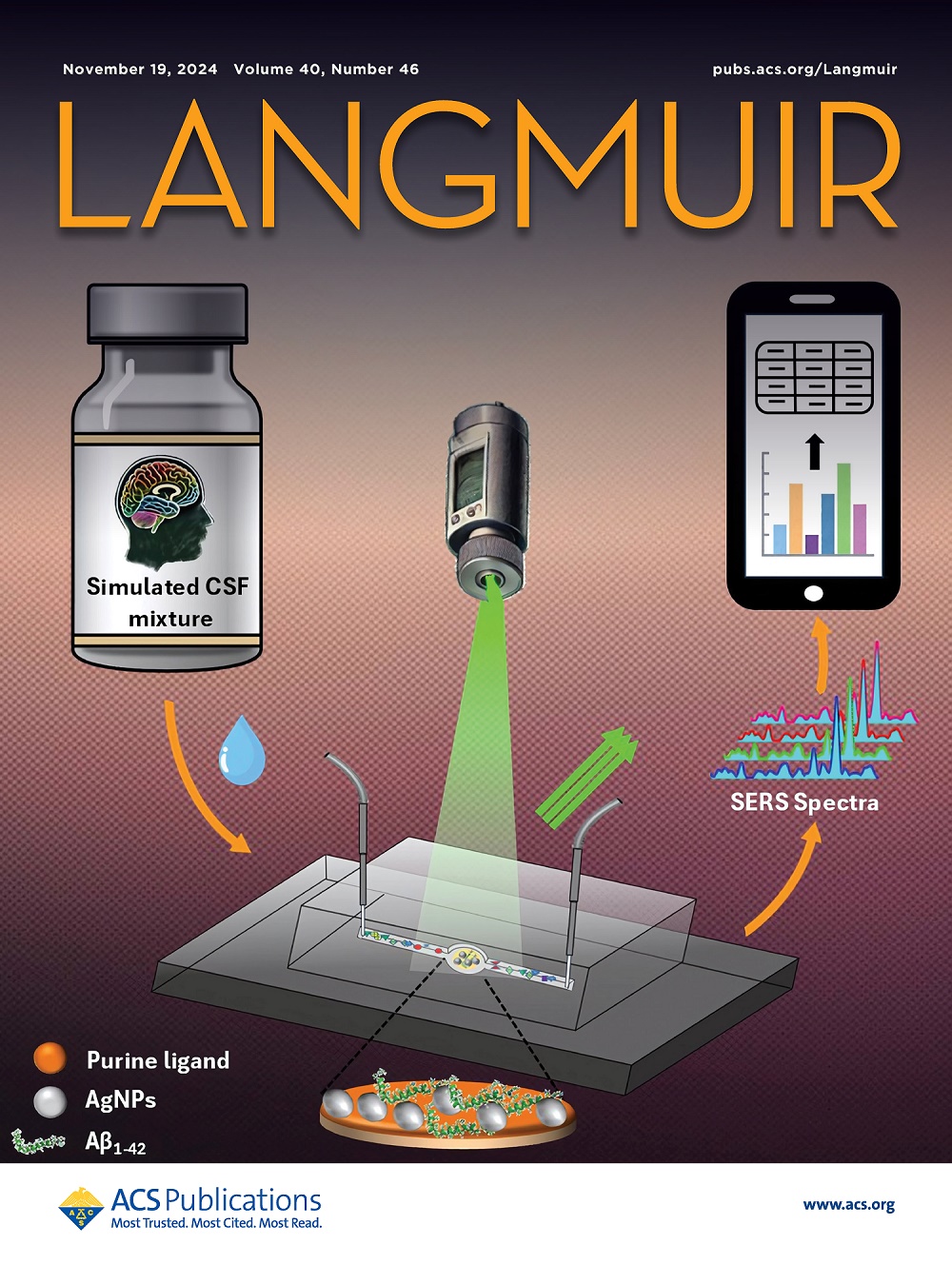

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: