富勒烯包覆纳米颗粒在粗糙表面的润滑行为。

IF 3.9

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

摘要

纳米颗粒具有优异的润滑性能,可用于粗糙的界面以减轻摩擦。本研究通过全原子分子动力学模拟(LAMMPS)研究了复合C540富勒烯包覆硅纳米颗粒在粗糙硅表面的润滑行为。系统分析了载荷、纳米粒子数量、滑动速度和表面粗糙度等关键因素的影响。研究结果表明,在高外加载荷下,增加纳米颗粒的数量可以有效地缓解应力集中,减少结构变形和摩擦。然而,过量会导致明显的突出,增加结构变形。由于探针和纳米颗粒的运动模式保持一致,速度变化不会显著影响摩擦或结构变形。然而,在低外加载荷下,探针驱动的纳米颗粒运动成为摩擦能量耗散的主要因素。在不同粗糙度表面上观察到纳米颗粒的总动能与摩擦力之间存在正相关关系。随着表面粗糙度的增加,过量纳米颗粒的负面影响变得更加明显。确定最佳纳米颗粒数量为防止应力集中引起的结构变形所需的最小量。在高负荷条件下,纳米颗粒的最佳浓度约为88.8%,浓度每增加3.55%,结构变形减少0.45%,摩擦减少0.59 nN。在低负荷条件下,不同表面粗糙度水平的最佳浓度范围为15%至30%,与峰值动能条件相比,摩擦减少了30%至55%。在低滑动速度下,纳米颗粒完全适应衬底凹槽,确保探针和纳米颗粒在不同速度下遵循几乎相同的相互作用模式,使摩擦与滑动速度无关。然而,在高速下,纳米颗粒作为磨料颗粒,导致结构变形和摩擦的显著增加。在平面上,摩擦力与施加的载荷成正比,与纳米颗粒的数量无关。这项研究提供了纳米颗粒在粗糙表面上的原子水平的润滑,阐明了纳米颗粒浓度如何在不同条件下控制润滑性能。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Lubrication Behavior of Fullerene-Coated Nanoparticles on Rough Surfaces.

Nanoparticles exhibit excellent lubrication properties and are utilized on rough interfaces to mitigate friction. This study investigates the lubrication behavior of composite C540 fullerene-coated silicon nanoparticles on rough silicon surfaces through all-atom molecular dynamics simulations (LAMMPS). The effects of key factors, including applied load, nanoparticle quantity, sliding velocity, and surface roughness, are systematically analyzed. Our results show that under high applied loads, increasing nanoparticle quantity effectively alleviates stress concentration, reducing both structural deformation and friction. However, excessive quantities cause pronounced protrusions that increase structural deformation. Velocity changes do not significantly impact friction or structural deformation, as the motion patterns of the probe and nanoparticles remain consistent. However, under low applied loads, probe-driven nanoparticle motion becomes the dominant factor in frictional energy dissipation. A positive correlation between the total kinetic energy of nanoparticles and friction force is observed across different roughness surfaces. The negative effects of excessive nanoparticles become more pronounced with increasing surface roughness. The optimal nanoparticle quantity is determined to be the minimum required to prevent stress-concentration-induced structural deformation. The optimal nanoparticle concentration reaches approximately 88.8% under high-load conditions, with each 3.55% increase in concentration resulting in a 0.45% reduction in structural deformation and a 0.59 nN decrease in friction. Under low-load conditions, the optimal concentration ranges from 15% to 30% across varying surface roughness levels, reducing friction by 30%-55% compared to the peak kinetic energy conditions. At low sliding velocities, nanoparticles fully adapt to substrate grooves, ensuring the probe and nanoparticles follow nearly identical interaction patterns at different velocities, making friction independent of sliding velocity. However, at high velocities, the nanoparticles act as abrasive particles, causing significant increases in both structural deformation and friction. On flat surfaces, friction is proportional to the applied load and remains independent of nanoparticle quantity. This study provides atomic-level insights into nanoparticle lubrication on rough surfaces, elucidating how nanoparticle concentration governs lubrication performance under varying conditions.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

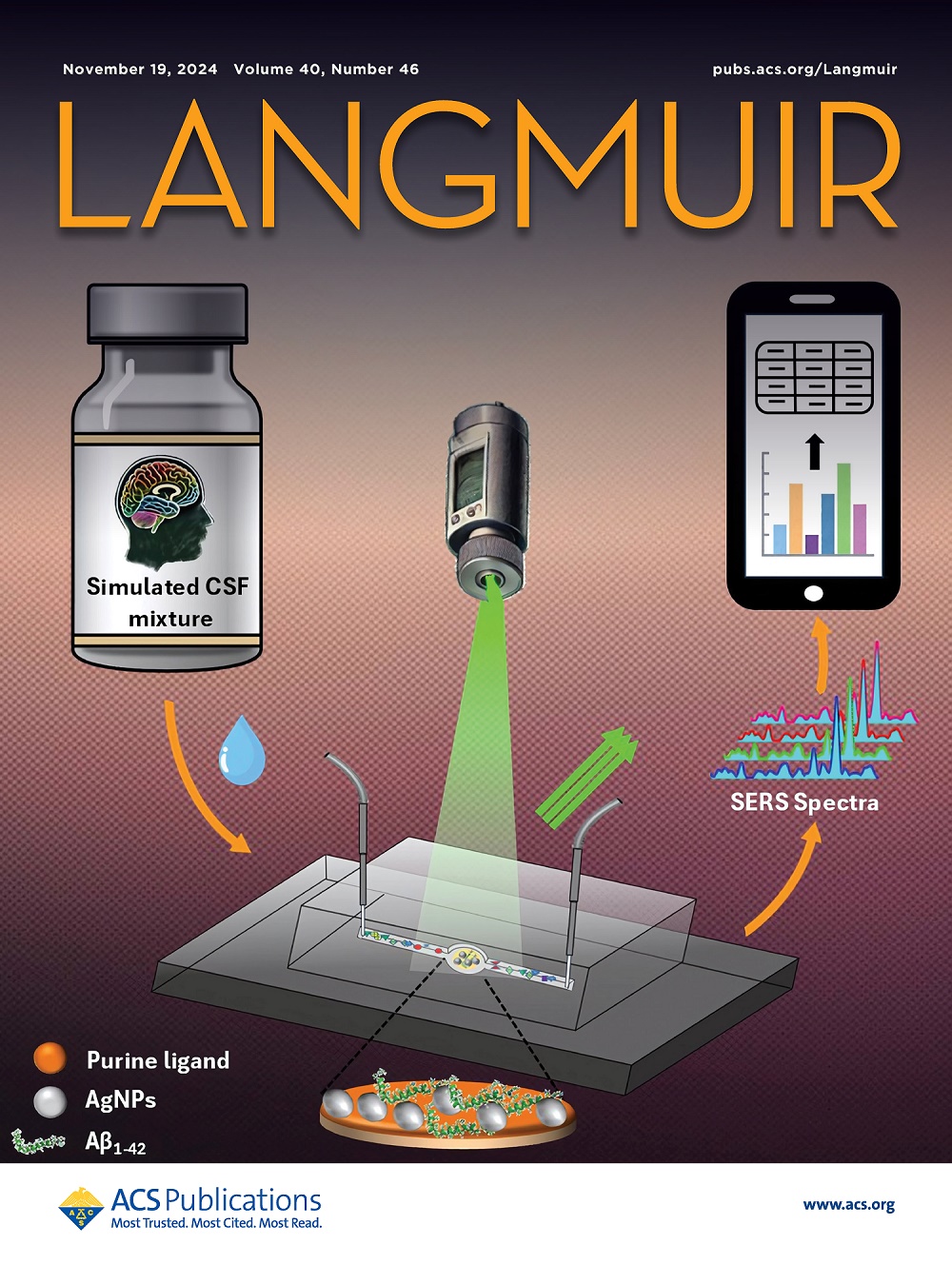

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: