新型微环旋转床:流体力学和液-液分散研究

IF 4

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

摘要

微环旋转床(MARB)是一种新设计的反应器,它集成了高重力场和微尺度效应,可以实现高效的液体混合。本研究系统地研究了MARB的流体力学和液液分散特性,包括停留时间分布、液含率、能量耗散率和Sauter平均直径(d32)。建立了预测这些参数的数学相关性。结果表明,MARB反应器的流动模式与连续搅拌槽反应器相似。含液率随流量的增加而线性增加,随转速的增加而减小,而能量耗散率主要受转速的控制。值得注意的是,MARB具有出色的液-液分散性能,在5 L/min的流速下,最小d32为4.9 μm,并且与传统反应器相比,能效有所提高。凭借其简单,高通量和有效的设计,MARB为工业应用中的高效液-液分散提供了非常有前途的解决方案。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Novel microannular rotating bed: Hydrodynamics and liquid–liquid dispersion study

Microannular rotating bed (MARB) is a newly designed reactor that integrates high-gravity fields and microscale effects to enable efficient liquid mixing. This study systematically investigated the hydrodynamic and liquid–liquid dispersion characteristics of the MARB, including residence time distribution, liquid holdup, energy dissipation rate, and Sauter mean diameter (d32). Mathematical correlations for predicting these parameters were established. The results showed that the MARB operates with a flow pattern similar to that of a continuous stirred-tank reactor. Liquid holdup increased linearly with flow rate and decreased with rotational speed, while energy dissipation rate was primarily governed by rotational speed. Notably, the MARB demonstrated excellent liquid–liquid dispersion performance, attaining a minimum d32 of 4.9 μm at a flow rate of 5 L/min, along with improved energy efficiency compared to conventional reactors. With its simple, high-throughput, and effective design, the MARB offers a highly promising solution for efficient liquid–liquid dispersion in industrial applications.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

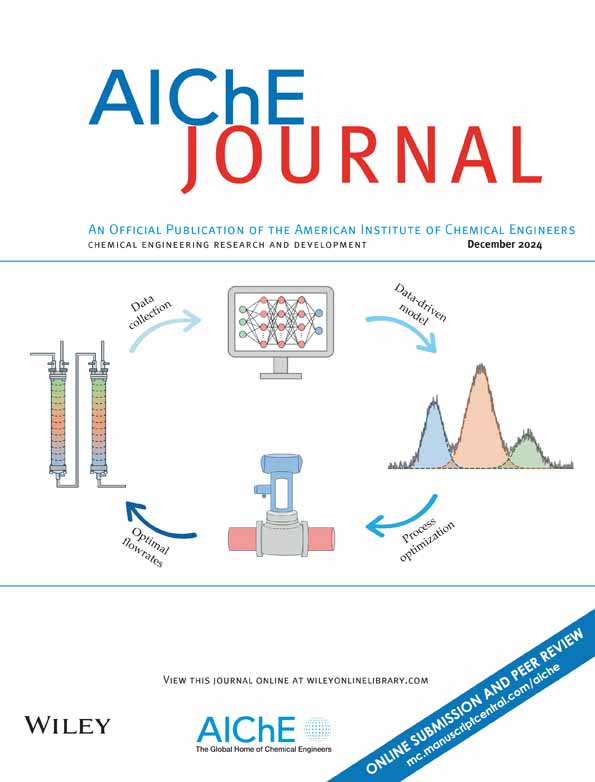

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: