6061铝合金阳极氧化涂层二次阴极沉积改性及性能研究

IF 3.9

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

摘要

本文提出了用不同浓度的H3PO4作为蚀刻液,对硬质阳极氧化铝涂层进行蚀刻,并通过阴极沉积Ni对其进行改性,制备陶瓷-金属复合涂层的方法。该方法成功地解决了硬质阳极氧化铝涂层硬度低、耐磨性差的问题。系统研究了不同浓度H3PO4蚀刻后硬质阳极氧化铝涂层与Ni层的结合效果,并进行了摩擦、腐蚀和涂层结合试验。结果表明:AA4%样品中的Ni离子完全渗透到硬质阳极氧化铝涂层中,氧化层与Ni层之间实现了良好的界面融合;涂层的主要成分是Al2O3和Ni。AA4%样品具有优异的耐磨性和较强的涂层结合力。在5 N载荷作用下,AA4%试样的磨损宽度比AA试样减小了52.49%,磨损深度几乎不可见。同时,Ni的沉积降低了镀层的化学稳定性,导致复合镀层的耐腐蚀性下降。AA4%试样的腐蚀速率比AA试样提高了1.7522 × 107%。综上所述,硬质阳极氧化铝涂层经二次Ni沉积处理后的耐磨性得到显著提高,为陶瓷-金属复合涂层在摩擦领域的应用提供了重要的指导意义。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Study on the Secondary Cathodic Deposition Modification and Properties of Anodic Oxidation Coating on 6061 Aluminum Alloy

This paper proposes a method for preparing a ceramic-metal composite coating by using different concentrations of H3PO4 as an etching solution to etch the hard anodized aluminum oxide coating and modify it by cathode deposition of Ni. This method successfully solves the problem of low hardness and poor wear resistance of the hard anodized aluminum coating. The bonding effect between the hard anodized aluminum coating and the Ni layer after etching with different concentrations of H3PO4 was systematically studied, and friction, corrosion and coating bonding tests were carried out. The results show that the Ni ions in the AA4% sample completely penetrated into the hard anodized aluminum coating, and a good interface fusion was achieved between the oxide layer and the Ni layer. The main components of the coating are Al2O3 and Ni. The AA4% sample exhibited excellent wear resistance and strong coating bonding. Under a load of 5 N, the wear width of the AA4% sample is reduced by 52.49% compared with that of the AA sample, and the wear depth is almost invisible. At the same time, the deposition of Ni reduced the chemical stability of the coating, resulting in a decrease in the corrosion resistance of the composite coating. The corrosion rate of the AA4% sample increased by 1.7522 × 107% compared with the AA sample. In summary, the wear resistance of the hard anodized aluminum coating has been significantly improved after secondary Ni deposition treatment, which provides important guiding significance for the application of ceramic-metal composite coatings in the field of friction.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

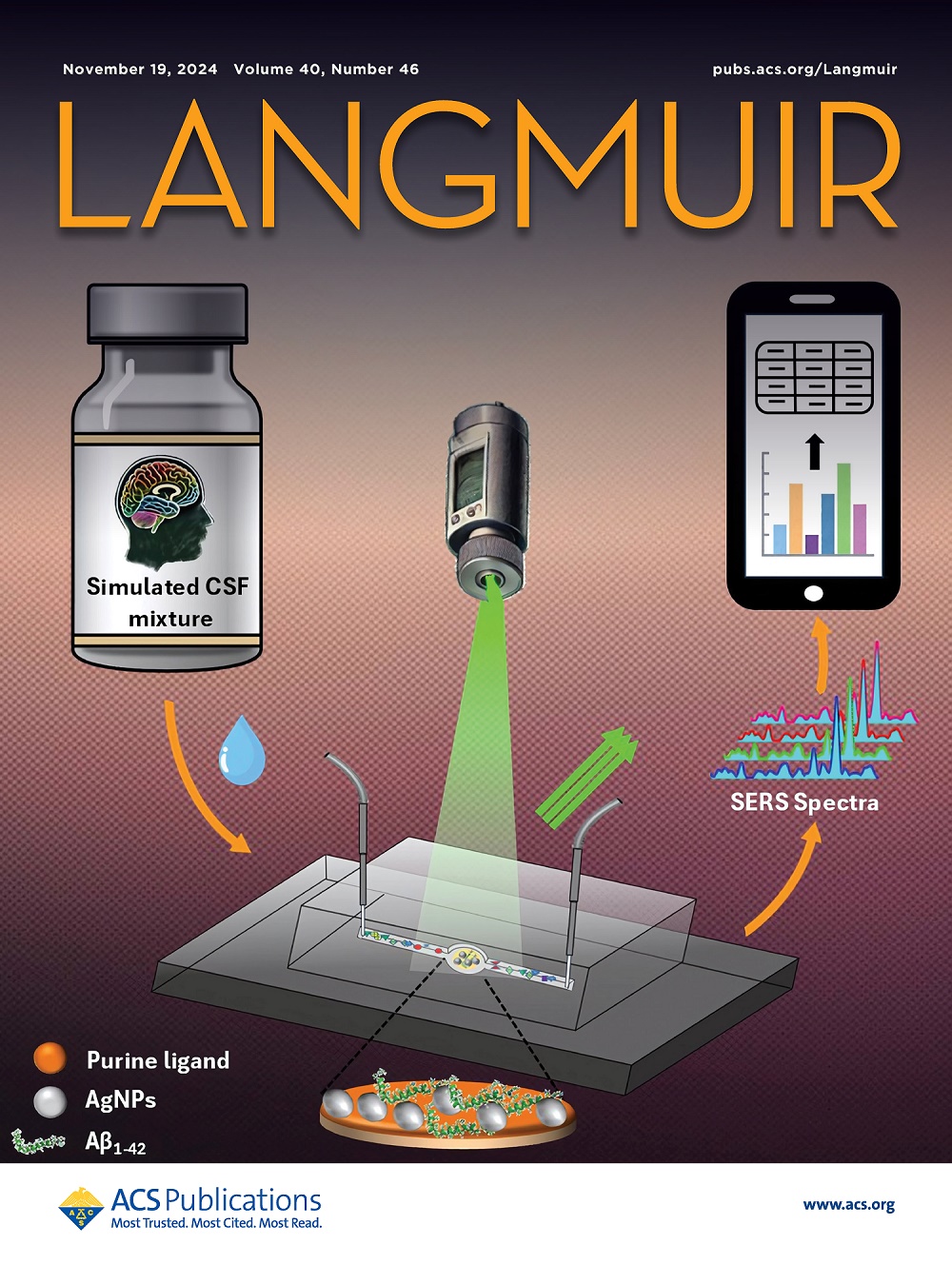

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: