液流电池中热塑性聚合物激光传输焊接的键合与粘附机理。

IF 3.9

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

摘要

粘合和粘合是聚合物复合材料成功的关键,特别是在氧化还原液流电池的密封过程中,塑料激光传输焊接技术开始获得关注。然而,影响焊接和微尺度键合机制的关键因素仍不完全清楚。本文采用正交试验方法系统分析了聚丙烯(PP)塑料激光焊接的最佳工艺参数和模式,并通过形貌分析和断裂力测试研究了界面结合机理。结果表明,当激光透过率约为40%,线能量密度在7 ~ 8 J/mm范围内时,可以获得最佳的粘附和密封性能。我们将热影响区(HAZ)、熔体流动混合区和核心区划分为三个不同的区域,这些区域显著提高了焊接结合强度。其中,核心区对键合强度贡献最大,具有絮状结构的致密纤维键合层,形成微晶粘接增强机制。熔体流动混合区具有不规则的大空腔,提供了混合联锁效应,而HAZ内稀疏的片状结合层代表了界面表面存在的伪粘附特征。此外,还探索了具有增强混合特性的凸起平台焊接,为提高焊接结合强度提供了独特的见解。本研究阐明了激光焊接粘接的基本因素和机理,优化后的工艺参数将显著提高PP塑料界面的粘接水平。此外,本研究还为能源行业摩擦剪切引起的焊接密封失效的预防和控制策略提供了额外的视角。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Bonding and Adhesion Mechanisms for Laser Transmission Welding of Thermoplastic Polymers in Liquid Flow Batteries.

Adhesion and bonding are critical to the success of polymer composites, particularly in the sealing processes of redox flow batteries, where laser transmission welding technology for plastics is beginning to gain traction. However, the key factors influencing welding and microscale bonding mechanisms remain incompletely understood. In this article, we systematically analyzed the optimal process parameters and patterns for laser welding of polypropylene (PP) plastics using orthogonal experiments and investigated the interfacial bonding mechanisms through morphology analysis and fracture force testing. The results indicate that an optimal adhesion and sealing performance can be achieved when the laser transmittance is approximately 40% and the line energy density is in the range of 7-8 J/mm. We categorized three distinct regions: heat-affected zone (HAZ), melt flow mixing zone, and core zone, which significantly enhance welding bond strength. Among these, the core zone, characterized by a dense fibrous bonding layer with a flocculent structure, contributes the most to bonding strength, forming a microriveting enhancement mechanism. The melt flow mixing zone features irregular large cavities that provide a mixing interlock effect, while the sparse flake-like bonding layer in the HAZ represents pseudo-adhesion characteristics present on the interface surface. Furthermore, raised-platform welding with enhanced mixing features was also explored, offering distinct insights into improving the welding bond strength. This study elucidates the essential factors and mechanisms of laser welding adhesion, and the optimized process parameters will significantly enhance the bonding level of the PP plastic interfaces. Additionally, this research provides additional perspectives on prevention and control strategies for welding seal failure caused by friction shear in the energy industry.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

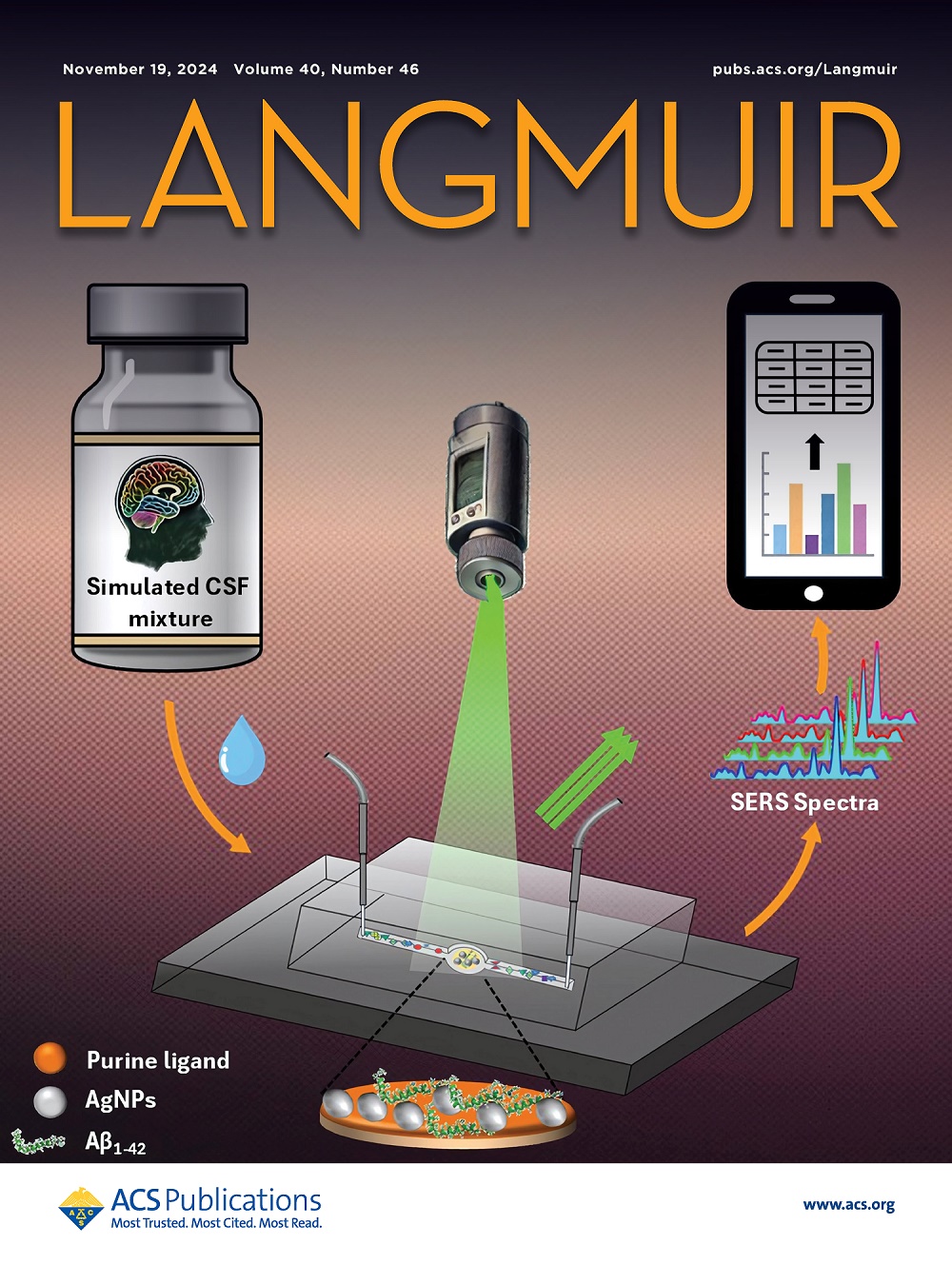

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: