催化膜反应器中共产芳烃与无co氢的有效耦合

IF 3.5

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

摘要

利用钼/沸石催化剂进行甲烷脱氢芳构化是一项很有前途的技术,它能将甲烷直接转化为有价值的芳烃和氢。然而,非氧化MDA面临两个主要障碍:热力学限制和快速催化剂失活。此外,氧化丙二醛经常经历不必要的氧化成CO,降低产物选择性和阻碍有效的H2分离。我们提出了一种有效的耦合策略,通过将水裂解集成到催化膜反应器(CMR)中来共同生产芳烃和无co的H2。与固定床反应器(FBR)相比,CMR不仅在1000 min后焦炭生成量减少了5倍,芳香收率提高了10倍以上,而且在水侧获得了不含co的H2。此外,还展示了一种新的再生方法,即水裂解结合简单关闭CH4,将焦炭在CMR两侧分别转化为有价值的无CO的H2和CO,从而提高了MDA工艺的技术经济可行性。本文章由计算机程序翻译,如有差异,请以英文原文为准。

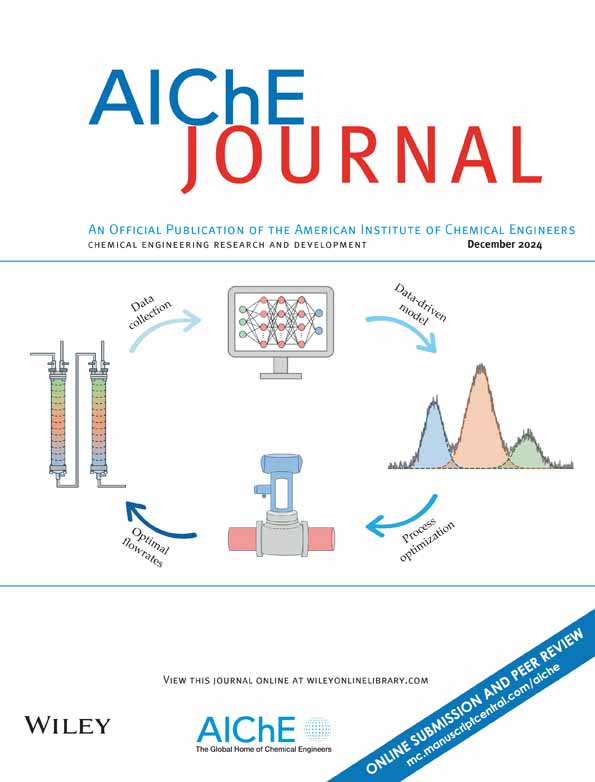

An effective coupling for coproducing aromatics and CO-free hydrogen in a catalytic membrane reactor

Methane dehydroaromatization (MDA) using Mo/zeolite catalysts is a promising technology that enables the direct conversion of methane into valuable aromatics and hydrogen. However, non-oxidative MDA suffers two main obstacles: thermodynamic limitations and rapid catalyst deactivation. Additionally, oxidative MDA often undergoes undesired oxidation to CO, reducing product selectivity and hindering efficient H2 separation. We present an effective coupling strategy to coproduce aromatics and CO-free H2 by integrating water splitting into a catalytic membrane reactor (CMR). Compared with the fixed-bed reactor (FBR), our CMR not only reduces coke formation by five times and increases aromatic yield over 10-fold after 1000 min, but also obtains CO-free H2 on the water side. Further, a novel regeneration method is demonstrated by water splitting coupled with simply shutting off CH4, transforming the coke into valuable CO-free H2 and CO on both sides of our CMR, respectively, and enhancing the techno-economic viability of the MDA process.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: