通过催化膜反应器生产绿色氨:通过实验和模拟验证概念

IF 3.5

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

摘要

氨(NH3)在化肥生产中起着至关重要的作用,但与哈伯-博施工艺相比,一种节能的 NH3 生产工艺亟待开发。催化膜反应器(CMR)将 Ru(10 wt%)/Cs/MgO 催化剂的反应和磺化(3-巯基丙基)三甲氧基硅烷(MPTMS)膜的膜分离集成在一个装置中,用于在 300°C 和 200-300 kPa 下生产绿色 NH3。结果,膜渗透侧的 NH3 摩尔分数大大提高到 0.031-0.046,是填料床反应器中 0.0028-0.0039 的 10 倍,转化率也从 ~0.5% 提高到 6%-9%。对 CMR 进行了过程模拟,证实模拟性能与实验结果一致。工艺模拟和实验结果表明,提高进料压力和流速会降低膜渗透侧的 NH3 摩尔分数和转化率,因为高压比 NH3 更能促进 H2 和 N2 的渗透。本文章由计算机程序翻译,如有差异,请以英文原文为准。

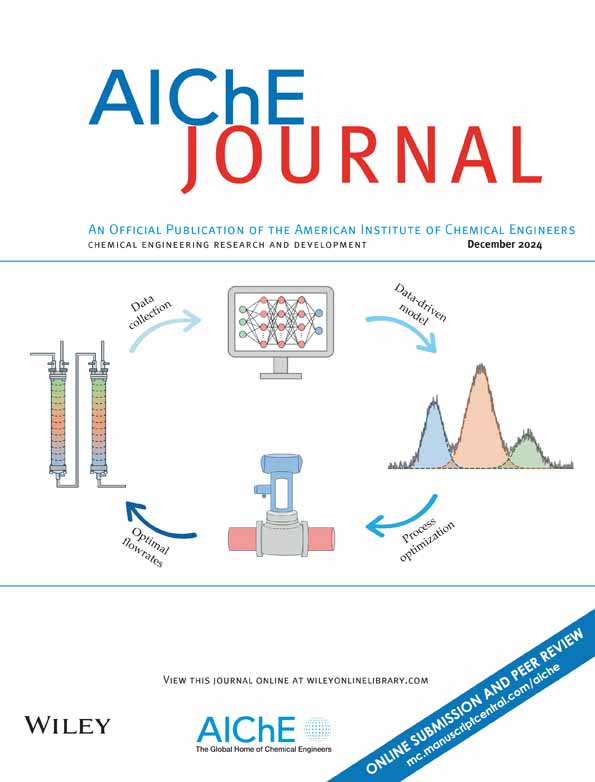

Green ammonia production via a catalytic membrane reactor: Proof of concept through experiments and simulations

Ammonia (NH3) plays a vital role in fertilizer production, but an energy-saving NH3 production process compared to the Haber–Bosch process is urgently being developed. A catalytic membrane reactor (CMR) that integrates the reaction with a Ru (10 wt%)/Cs/MgO catalyst and the membrane separation with a sulfonated (3-mercaptopropyl)trimethoxysilane (MPTMS) membrane in one unit was used for green NH3 production at 300°C and 200–300 kPa. Consequently, the NH3 mole fraction was greatly increased to 0.031–0.046 in the permeate side of the membrane, which is 10 times higher than 0.0028–0.0039 in a packed bed reactor, together with an improved conversion from ~0.5% to 6%–9%. Process simulation of the CMR was formulated, confirming that the simulated performance agreed with experiments. Process simulation and experimental results show that increasing the feed pressure and flow rate would decrease the NH3 molar fraction in the permeate side of the membrane and conversion, since high pressures promote H2 and N2 permeation more than NH3.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: