盾构隧道分段全尺寸加载试验:衬砌结构的承载性能和破坏模式

IF 8.3

1区 工程技术

Q1 ENGINEERING, CIVIL

引用次数: 0

摘要

为探索衬砌结构的承载性能和破坏模式,通过液压加载系统对三环交错拼装盾构隧道节段进行了全尺寸加载试验。在实验研究中,分析了分段的内力、收敛变形和位移,以及螺栓的内力。根据实验结果,得出内力与变形之间的关系,从而确定盾构隧道在每个阶段的剩余承载力。加载过程中,区段最大弯矩的演变分为三个阶段,其中弹性阶段是最主要和最长的阶段,在此阶段区段弯矩增加最大。收敛变形发展和节段错位发展分为两个阶段。加载结束时,节段的最大正收敛值和负收敛值分别达到 61.22 毫米和-57.69 毫米。此外,最大节段偏差为 3.67 mm,发生在 90° 方向上。当最大收敛值达到 25.03 mm 时,分段出现裂缝。此外,当最大收敛值达到 32.73 mm 时,分段的腰部连接处出现断裂迹象。当区段的最大收敛值达到 38.93 毫米时,腰部连接处的混凝土开始碎裂,这被定义为剪切破坏类型。最后,可以利用变形和内力之间的相应关系来评估盾构隧道在断面破坏期间的承载能力。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Full-scale loading test for shield tunnel segments: Load-bearing performance and failure patterns of lining structures

To explore the load-bearing performance and the failure patterns of the lining structures, a full-scale loading test on the three-ring staggered assembled shield tunnel segments is carried out through a hydraulic loading system. In the experimental study, the segments’ internal force, convergence deformation, and displacement, and the bolts’ internal force, are analyzed. According to the experimental results, the relationship between internal force and deformation is obtained to determine the residual bearing capacity of the shield tunnel at each stage. Three stages are specified for the evolution of the segment’s maximum bending moment during the loading process, in which, the elastic stage is the main and longest stage, in which the bending moment of the segment increases the most. There are two stages for convergence deformation development and segment misalignment development. At the end of loading, the segment’s maximum positive and negative convergence values reach 61.22 and −57.69 mm, respectively. Besides, the maximum segment misalignment is 3.67 mm, which occurs in the direction of 90°. The segment cracks when its maximum convergence value reaches 25.03 mm. Moreover, there are signs of fracturing on the waist joint of the segment when its maximum convergence value reaches 32.73 mm. The concrete at the waist joint starts fracturing in pieces when the segment’s maximum convergence value reaches 38.93 mm, which is defined as the type of shear failure. Finally, the bearing capacity of shield tunnels during segment failure period can be evaluated by using the corresponding relationship between deformation and internal force.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

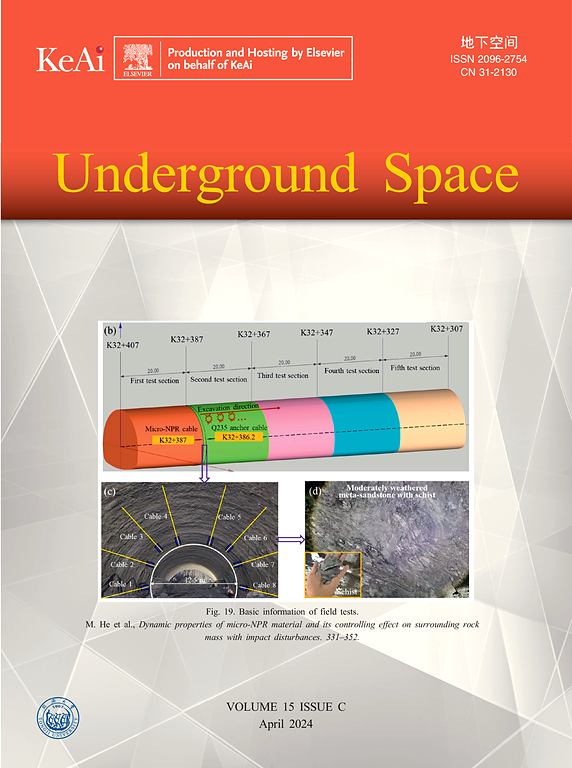

Underground Space

ENGINEERING, CIVIL-

CiteScore

10.20

自引率

14.10%

发文量

71

审稿时长

63 days

期刊介绍:

Underground Space is an open access international journal without article processing charges (APC) committed to serving as a scientific forum for researchers and practitioners in the field of underground engineering. The journal welcomes manuscripts that deal with original theories, methods, technologies, and important applications throughout the life-cycle of underground projects, including planning, design, operation and maintenance, disaster prevention, and demolition. The journal is particularly interested in manuscripts related to the latest development of smart underground engineering from the perspectives of resilience, resources saving, environmental friendliness, humanity, and artificial intelligence. The manuscripts are expected to have significant innovation and potential impact in the field of underground engineering, and should have clear association with or application in underground projects.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: