研究 ABS 对 PETG-ABS 混合物的机械性能、形态、可印刷性和 4D 印刷的影响

IF 4.2

3区 材料科学

Q2 MATERIALS SCIENCE, MULTIDISCIPLINARY

引用次数: 0

摘要

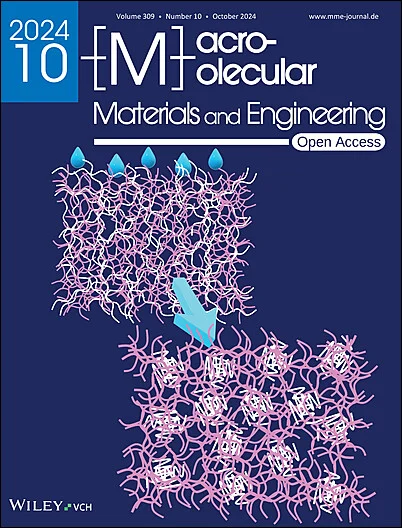

封面:Mostafa Baghani 及其合作者撰写的文章 2400038 的封面图片显示了三维打印 PETG-ABS 混合物在约 100 °C 的恢复温度下以时间为单位的自由形状恢复过程。这种混合物是通过在内部混合器中以 200 °C 的温度和 60 rpm 的转速进行 6 分钟的熔融混合制备的,最终部件是通过基于颗粒材料的挤出方法进行 3D 打印的。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Investigating the Effect of ABS on the Mechanical Properties, Morphology, Printability, and 4D Printing of PETG-ABS Blends

Front Cover: The cover image of article 2400038 by Mostafa Baghani and co-workers shows the free shape recovery process of 3D printed PETG-ABS blend in terms of time at a recovery temperature of about 100 °C. This blend is prepared by melt mixing in the internal mixer at a temperature of 200 °C and 60 rpm for 6 minutes, and the final part is 3D printed by granule-based material extrusion method.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

Macromolecular Materials and Engineering

工程技术-材料科学:综合

CiteScore

7.30

自引率

5.10%

发文量

328

审稿时长

1.6 months

期刊介绍:

Macromolecular Materials and Engineering is the high-quality polymer science journal dedicated to the design, modification, characterization, processing and application of advanced polymeric materials, including membranes, sensors, sustainability, composites, fibers, foams, 3D printing, actuators as well as energy and electronic applications.

Macromolecular Materials and Engineering is among the top journals publishing original research in polymer science.

The journal presents strictly peer-reviewed Research Articles, Reviews, Perspectives and Comments.

ISSN: 1438-7492 (print). 1439-2054 (online).

Readership:Polymer scientists, chemists, physicists, materials scientists, engineers

Abstracting and Indexing Information:

CAS: Chemical Abstracts Service (ACS)

CCR Database (Clarivate Analytics)

Chemical Abstracts Service/SciFinder (ACS)

Chemistry Server Reaction Center (Clarivate Analytics)

ChemWeb (ChemIndustry.com)

Chimica Database (Elsevier)

COMPENDEX (Elsevier)

Current Contents: Physical, Chemical & Earth Sciences (Clarivate Analytics)

Directory of Open Access Journals (DOAJ)

INSPEC (IET)

Journal Citation Reports/Science Edition (Clarivate Analytics)

Materials Science & Engineering Database (ProQuest)

PASCAL Database (INIST/CNRS)

Polymer Library (iSmithers RAPRA)

Reaction Citation Index (Clarivate Analytics)

Science Citation Index (Clarivate Analytics)

Science Citation Index Expanded (Clarivate Analytics)

SciTech Premium Collection (ProQuest)

SCOPUS (Elsevier)

Technology Collection (ProQuest)

Web of Science (Clarivate Analytics)

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: