两步超快高温烧结法制备多孔硅酸钙陶瓷及其特性

IF 1.8

4区 材料科学

Q2 MATERIALS SCIENCE, CERAMICS

引用次数: 0

摘要

通过超快高温工艺在几分钟内制备出了多孔硅酸钙陶瓷。研究了烧结电流和淀粉含量对相组成、孔结构、抗压强度和透气性的影响。在水合硅酸钙、碳酸钙和淀粉的快速分解过程中,可以形成均匀的孔隙。优化组合显示出较高的抗压强度(超过 7 兆帕)、孔隙率(60.8%)和透气性(379.4 升/平方米秒)。结果表明,超快高温烧结法比传统炉烧结法能在更短的时间内获得均匀的多孔结构。本文章由计算机程序翻译,如有差异,请以英文原文为准。

Preparation and property of porous calcium silicate ceramic by two-step ultrafast high-temperature sintering

Porous calcium silicate ceramic has been prepared by ultrafast high-temperature process in several minutes. The effect of sintering current and starch content on the phase composition, pore structure, compressive strength, and air permeability have been investigated. Homogeneous pores can be formed during the fast decomposition of calcium silicate hydrate, calcium carbonate, and starch. The optimized composition shows the high compressive strength (over 7 MPa), porosity (60.8%), and air permeability (379.4 L/m2 s). Results showed that the ultrafast high-temperature sintering method can achieve homogenous porous structure in much shorter time than conventional furnace sintering.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

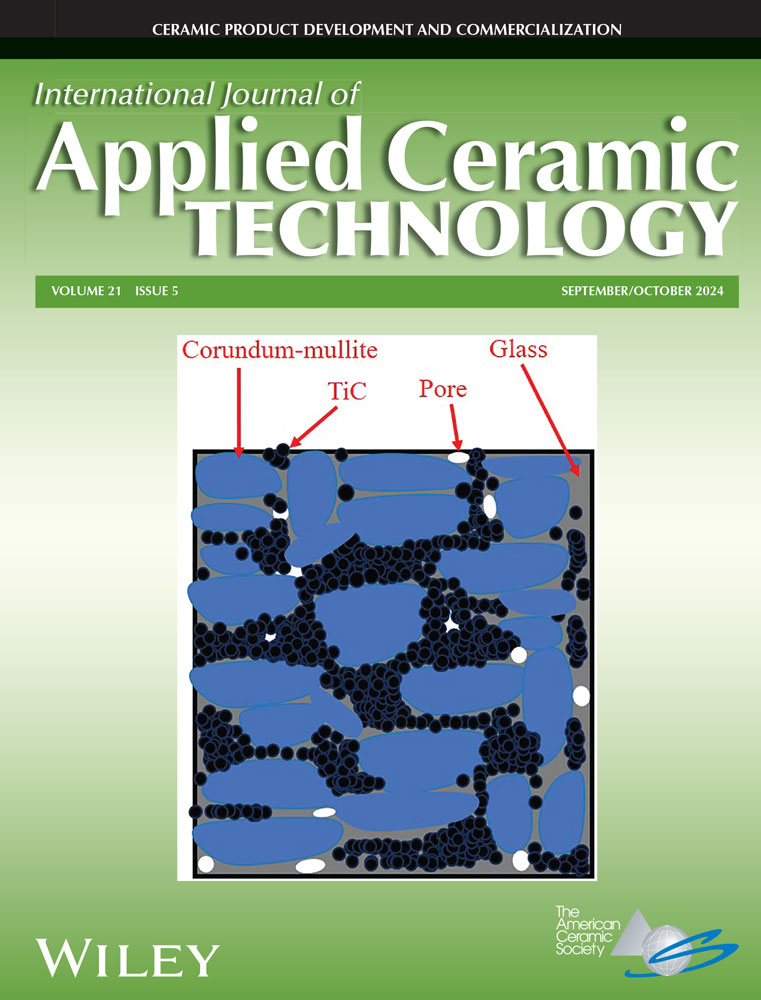

International Journal of Applied Ceramic Technology

工程技术-材料科学:硅酸盐

CiteScore

3.90

自引率

9.50%

发文量

280

审稿时长

4.5 months

期刊介绍:

The International Journal of Applied Ceramic Technology publishes cutting edge applied research and development work focused on commercialization of engineered ceramics, products and processes. The publication also explores the barriers to commercialization, design and testing, environmental health issues, international standardization activities, databases, and cost models. Designed to get high quality information to end-users quickly, the peer process is led by an editorial board of experts from industry, government, and universities. Each issue focuses on a high-interest, high-impact topic plus includes a range of papers detailing applications of ceramics. Papers on all aspects of applied ceramics are welcome including those in the following areas:

Nanotechnology applications;

Ceramic Armor;

Ceramic and Technology for Energy Applications (e.g., Fuel Cells, Batteries, Solar, Thermoelectric, and HT Superconductors);

Ceramic Matrix Composites;

Functional Materials;

Thermal and Environmental Barrier Coatings;

Bioceramic Applications;

Green Manufacturing;

Ceramic Processing;

Glass Technology;

Fiber optics;

Ceramics in Environmental Applications;

Ceramics in Electronic, Photonic and Magnetic Applications;

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: