Hybrid rule‐based and optimization‐driven framework for the synthesis of end‐to‐end optimal pharmaceutical processes

IF 3.5

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

Abstract

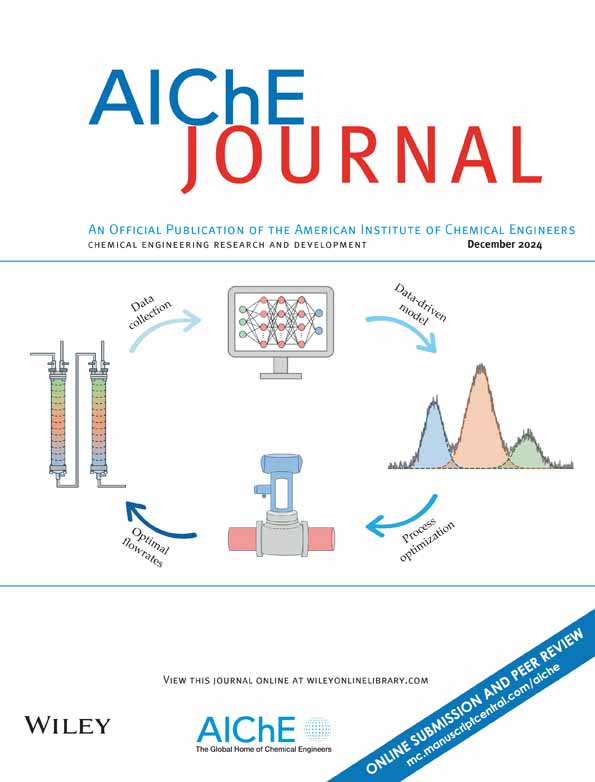

The modernization of pharmaceutical manufacturing is driving a shift from traditional batch processing to continuous alternatives. Synthesizing end‐to‐end optimal (E2EO) manufacturing routes is crucial for the pharmaceutical industry, especially when considering multiple operating modes—such as batch, continuous, or hybrid (containing both batch and continuous steps). A major challenge is the ability to compare these manufacturing alternatives across different operating modes, hindering optimal superstructure synthesis. To bridge this gap, this study introduces a hierarchical framework for the synthesis of E2EO manufacturing routes, employing a hybrid rule‐based and optimization‐driven approach. This method optimizes flowsheets modeled using PharmaPy through a simulation‐optimization technique with modest computational requirements. The effectiveness of the proposed framework is demonstrated through a case study on the manufacturing of the cancer therapy drug Lomustine. Two distinct manufacturing scenarios are analyzed to generate E2EO manufacturing campaigns tailored to the specific chemistries and process configurations, considering process efficiency and sustainable manufacturing.混合基于规则和优化驱动的框架,用于端到端最佳制药工艺的合成

医药生产的现代化正在推动从传统的批量加工到连续替代的转变。合成端到端最优(E2EO)制造路线对于制药行业至关重要,特别是在考虑多种操作模式时,例如批量,连续或混合(包含批量和连续步骤)。一个主要的挑战是在不同的操作模式下比较这些制造方案的能力,这阻碍了最佳的上层结构合成。为了弥补这一差距,本研究采用基于规则和优化驱动的混合方法,引入了E2EO制造路线综合的分层框架。该方法通过适度计算需求的模拟优化技术来优化使用PharmaPy建模的流程。通过对癌症治疗药物洛莫司汀生产的案例研究,证明了所提出框架的有效性。分析了两种不同的制造方案,以生成针对特定化学物质和工艺配置的E2EO制造活动,同时考虑到工艺效率和可持续制造。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: