Modeling bubble dynamics in rotating foam stirrer reactors: A computational fluid dynamics approach incorporating gas–solid interactions

IF 3.5

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

Abstract

The rotating foam stirrer reactor (RFSR) employs a donut-shaped porous solid foam stirrer to enhance mass transfer in multiphase systems. However, the complex structure of the foam stirrer presents significant challenges for developing efficient computational models, impeding reactor optimization and scale-up. In this work, we developed a novel bubble breakup and coalescence model based on Liao's framework, incorporating the effects of the rotating porous media. A new bubble breakup mechanism was proposed, accounting for the friction and collisions between bubbles and the struts within the foam stirrer. By integrating this model with a porous media approach, we constructed a simplified three-dimensional computational fluid dynamics model of the RFSR. Simulation results reveal that bubble breakup within the porous medium is primarily driven by gas–solid interactions, leading to enhanced mass transfer. The model accurately predicts gas holdup and bubble size distributions, providing valuable insights for reactor design and scale-up.旋转泡沫搅拌反应器中的气泡动力学建模:一种结合气固相互作用的计算流体动力学方法

旋转泡沫搅拌反应器(RFSR)采用环形多孔固体泡沫搅拌器来增强多相体系的传质。然而,泡沫搅拌器的复杂结构给建立高效的计算模型带来了巨大的挑战,阻碍了反应器的优化和放大。在这项工作中,我们基于廖的框架建立了一个新的气泡破裂和聚并模型,并考虑了旋转多孔介质的影响。提出了一种新的气泡破碎机制,考虑了泡沫搅拌器内气泡与支柱之间的摩擦和碰撞。将该模型与多孔介质方法相结合,建立了一个简化的RFSR三维计算流体力学模型。模拟结果表明,多孔介质中的气泡破碎主要是由气固相互作用驱动的,从而导致传质增强。该模型准确地预测了气含率和气泡大小分布,为反应器设计和放大提供了有价值的见解。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

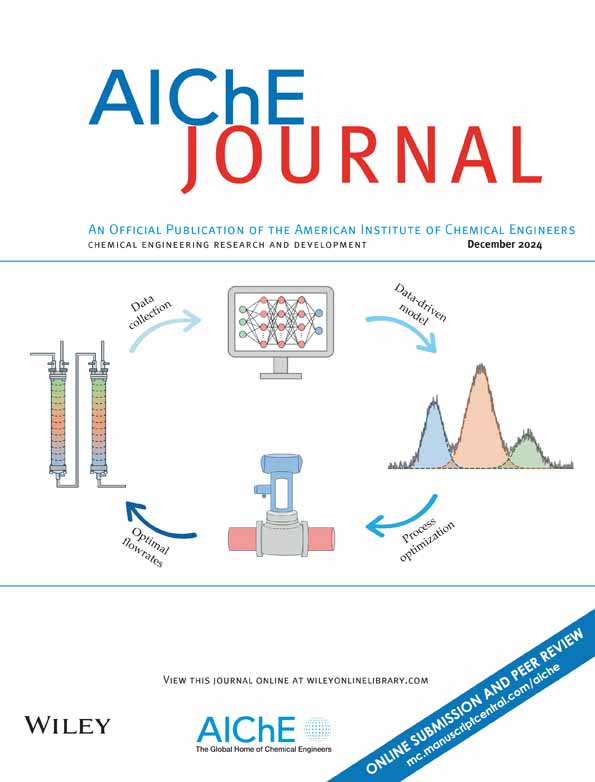

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: