Research on the Synergistic Enhancement of Corrosion Resistance and Wear Resistance of Ni–W–B-Based Coatings by Nano CeO2 and PDA Functionalized VC

IF 3.7

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

Abstract

Metal-based composite coatings have been widely studied for their excellent properties. In order to improve the properties of nickel tungsten boron (Ni–W–B) matrix, Ni–W–B/PC coatings were prepared by electrodeposition in the presence of polydopamine functionalized VC (P–VC) and cerium oxide (CeO2) nanoparticles. The effect of cerium oxide content in the nanomaterials on the properties of Ni–W–B coatings was investigated. The results showed that the prepared coatings were dense, uniform, and crack-free, and the best performance was achieved at a cerium oxide content of 2 g/L. The addition of CeO2 nanoparticles can fill the tiny defects in the coating and optimize the coating structure. The addition of these two materials refines the size of the coating grains. In terms of coating performance, the corrosion resistance of the composite coating was enhanced with the addition of CeO2 at a certain P–VC concentration, and the total impedance of the composite coating was 24,030 Ω·cm2, which was 4.8 times higher than that of the Ni–W–B coating and 1.7 times higher than that of the Ni–W–B/P–VC coating. In addition, the hardness of the Ni–W–B/PC-2 composite coating reached 1033.93 HV at a CeO2 content of 2 g/L. The wear resistance of this composite coating was also optimized. Compared with the Ni–W–B/P–VC composite coating, the average coefficient of friction was reduced by 8.8%, and the wear resistance of the composite coating was further improved, which was attributed to the synergistic effect of the two materials. Moreover, the Ni–W–B/PC film has excellent hardness and corrosion resistance, which is promising for the application in harsh environments.

纳米CeO2与PDA功能化VC协同增强ni - w - b基涂层耐蚀耐磨性能的研究

金属基复合涂层以其优异的性能得到了广泛的研究。为了提高镍钨硼(Ni-W-B)基体的性能,在聚多巴胺功能化VC (P-VC)和氧化铈(CeO2)纳米粒子存在下,采用电沉积法制备了Ni-W-B /PC涂层。研究了纳米材料中氧化铈含量对Ni-W-B镀层性能的影响。结果表明:制备的涂层致密、均匀、无裂纹,其中氧化铈含量为2 g/L时性能最佳;CeO2纳米粒子的加入可以填补涂层中的微小缺陷,优化涂层结构。这两种材料的加入细化了涂层颗粒的尺寸。在涂层性能方面,在一定P-VC浓度下,CeO2的加入增强了复合涂层的耐蚀性,复合涂层的总阻抗为24030 Ω·cm2,是Ni-W-B涂层的4.8倍,是Ni-W-B / P-VC涂层的1.7倍。CeO2含量为2 g/L时,Ni-W-B /PC-2复合镀层的硬度达到1033.93 HV。并对复合涂层的耐磨性进行了优化。与Ni-W-B / P-VC复合涂层相比,平均摩擦系数降低了8.8%,复合涂层的耐磨性进一步提高,这是两种材料协同作用的结果。此外,Ni-W-B /PC薄膜具有优异的硬度和耐腐蚀性,在恶劣环境下的应用前景广阔。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

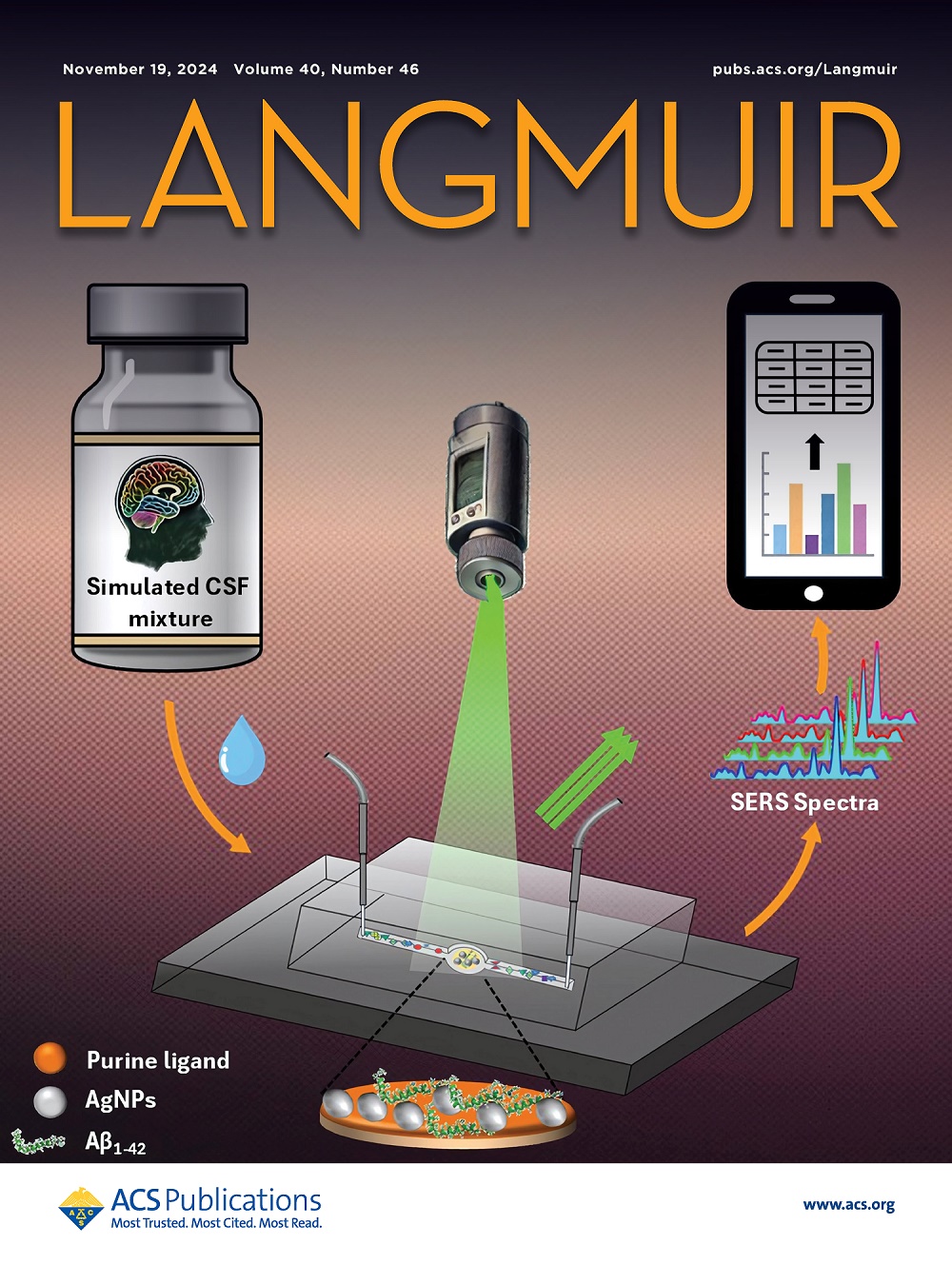

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: