Achievements in 3D printing of silica-based materials for bone tissue engineering

IF 5.4

2区 医学

Q1 BIOPHYSICS

引用次数: 0

Abstract

Silica-based materials have been commonly studied in the field of bone tissue regeneration, due to their high bioactivity and osteogenic properties. There are two main strategies to obtain silica-based materials, a melt-quenching process using high temperatures, or a sol-gel reaction which can be carried out at mild conditions. Both techniques allow the preparation of calcium silicates and bioactive glasses, but pure silica can only be prepared through the sol-gel method. Furthermore, current clinical treatments require personalized scaffolds and these materials can be combined with the use of 3D printing techniques to obtain patient-specific scaffolds in a fast and precise fabrication process. This review focuses on the different silica-based 3D printable materials available nowadays as well as their physical, chemical and biological properties. Using high temperature, composites can be developed using Fused Deposition Modelling (FDM), while pure silica scaffolds can be prepared through Selective Laser Sintering (SLS) using silica particles. Moreover, silica particles can be 3D printed when combining polymeric binders and SLS, Stereolitography (SLA) or Direct Ink Writing (DIW); however, binder has to be removed at high temperatures after 3D printing. Alternatively, 3D printable silica materials can be obtained at mild temperatures through DIW or SLA, in this case only allowing the printing of composites or hybrids so far, with different proportions of silica. The properties of the resultant materials as well as the main advantages and disadvantages of the printing approaches are summarized in this review, together with the future perspectives in the field of silica 3D printed scaffolds.

求助全文

约1分钟内获得全文

求助全文

来源期刊

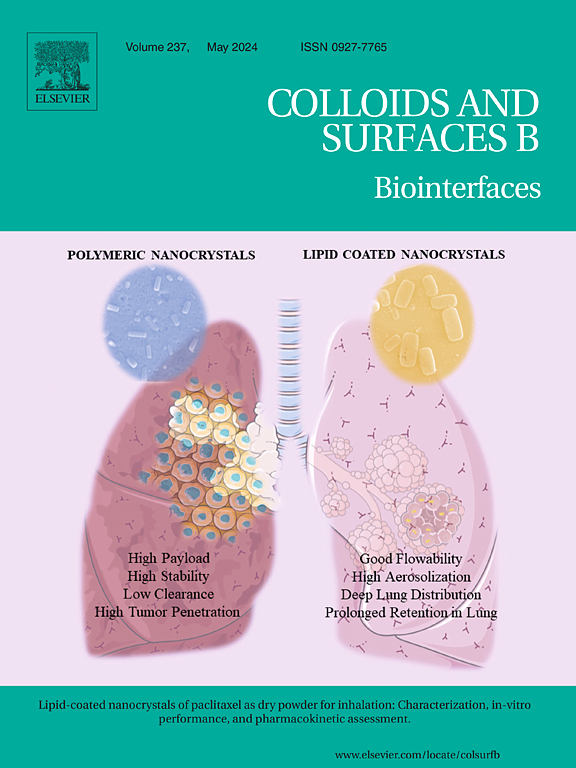

Colloids and Surfaces B: Biointerfaces

生物-材料科学:生物材料

CiteScore

11.10

自引率

3.40%

发文量

730

审稿时长

42 days

期刊介绍:

Colloids and Surfaces B: Biointerfaces is an international journal devoted to fundamental and applied research on colloid and interfacial phenomena in relation to systems of biological origin, having particular relevance to the medical, pharmaceutical, biotechnological, food and cosmetic fields.

Submissions that: (1) deal solely with biological phenomena and do not describe the physico-chemical or colloid-chemical background and/or mechanism of the phenomena, and (2) deal solely with colloid/interfacial phenomena and do not have appropriate biological content or relevance, are outside the scope of the journal and will not be considered for publication.

The journal publishes regular research papers, reviews, short communications and invited perspective articles, called BioInterface Perspectives. The BioInterface Perspective provide researchers the opportunity to review their own work, as well as provide insight into the work of others that inspired and influenced the author. Regular articles should have a maximum total length of 6,000 words. In addition, a (combined) maximum of 8 normal-sized figures and/or tables is allowed (so for instance 3 tables and 5 figures). For multiple-panel figures each set of two panels equates to one figure. Short communications should not exceed half of the above. It is required to give on the article cover page a short statistical summary of the article listing the total number of words and tables/figures.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: