Syngas chemical looping process: Ni–Fe bimetallic oxygen carriers for maximizing blue hydrogen yield

IF 3.5

3区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

Abstract

The syngas chemical looping (SCL) process is an advanced thermochemical approach for hydrogen production with in situ carbon capture. This article proposes a novel Ni–Fe bimetallic oxide in a three-reactor chemical looping system. In the moving bed reducer, a mixture of NiO and Fe3O4 is countercurrently reduced by syngas to Ni and Fe/FeO. In the oxidizer, the Fe/FeO mixture is oxidized back to Fe3O4 by steam, producing high-purity H2, while Ni remains unchanged. In the combustor, Ni is oxidized to NiO by air to supply heat, while Fe3O4 is maintained without further oxidation to Fe2O3. The reducer's operating conditions are optimized using the operating line diagram method and the multistage equilibrium model. Process simulation results show that the Ni–Fe oxygen carrier can increase blue hydrogen production efficiency by more than 5% compared to the Fe-based SCL process, while ensuring a carbon capture rate of over 99%.求助全文

约1分钟内获得全文

求助全文

来源期刊

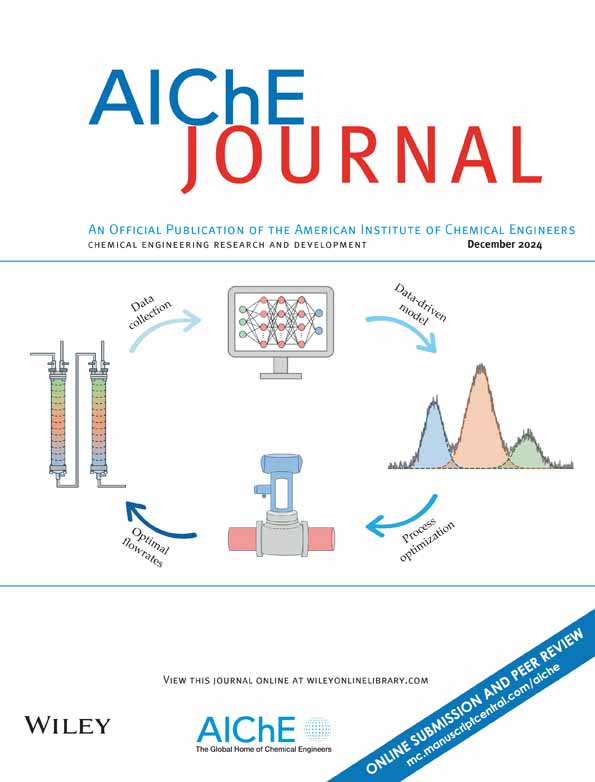

AIChE Journal

工程技术-工程:化工

CiteScore

7.10

自引率

10.80%

发文量

411

审稿时长

3.6 months

期刊介绍:

The AIChE Journal is the premier research monthly in chemical engineering and related fields. This peer-reviewed and broad-based journal reports on the most important and latest technological advances in core areas of chemical engineering as well as in other relevant engineering disciplines. To keep abreast with the progressive outlook of the profession, the Journal has been expanding the scope of its editorial contents to include such fast developing areas as biotechnology, electrochemical engineering, and environmental engineering.

The AIChE Journal is indeed the global communications vehicle for the world-renowned researchers to exchange top-notch research findings with one another. Subscribing to the AIChE Journal is like having immediate access to nine topical journals in the field.

Articles are categorized according to the following topical areas:

Biomolecular Engineering, Bioengineering, Biochemicals, Biofuels, and Food

Inorganic Materials: Synthesis and Processing

Particle Technology and Fluidization

Process Systems Engineering

Reaction Engineering, Kinetics and Catalysis

Separations: Materials, Devices and Processes

Soft Materials: Synthesis, Processing and Products

Thermodynamics and Molecular-Scale Phenomena

Transport Phenomena and Fluid Mechanics.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: