Thin Liquid Film View and Shear Stress During the Sliding of Air Bubbles on Tilted Plates

IF 3.7

2区 化学

Q2 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

Abstract

The challenge when studying the impact and sliding of free-rising air bubbles on tilted surfaces is an experimental limitation in obtaining the film thickness of thin liquid film (TLF) during the bubbles’ sliding on tilted surfaces. In this work, spatiotemporal evolution in the film thickness of the moving TLF between a sliding air bubble and a tilted plate was monitored by using a two-wavelength synchronized reflection interferometry microscopy (SRIM) technique. The evolution of the film thickness was directly determined from a timed series of monochromatic interference fringes recorded simultaneously at two different wavelengths. From the film thickness profile, a shear stress map at a given time was determined at different bubble sizes and inclination angles. Results showed that the film thickness of TLFs during the bubbles’ sliding on tilted surfaces was in the range of 300–1200 nm, depending on bubble size and tilting angles. Sliding of air bubbles on tilted plates over a thin gap with a few hundred nanometers thickness yielded shear stress in the order of 10–50 Pa. Both the larger bubble size and higher tilting angles yielded a higher shear stress. Experimental results were quantitatively compared to numerical results obtained using the Reynolds lubrication theory. A good match between the two results was achieved. Numerical results suggested that a maximum shear stress exerted on a tilted plate occurred at a 25° tilting angle. This is the first time that the spatiotemporal evolution of TLF during bubbles’ sliding on tilted surfaces has been achieved, and the shear stress exerted on the tilted surface has been directly determined.

气泡在倾斜板上滑动时的薄液膜视图和剪切应力

在研究自由上升气泡对倾斜表面的撞击和滑动时,面临的挑战是在气泡在倾斜表面滑动过程中获取液体薄膜(TLF)膜厚的实验限制。在这项工作中,利用双波长同步反射干涉显微镜(SRIM)技术监测了滑动气泡和倾斜板之间移动的 TLF 薄膜厚度的时空演变。通过在两个不同波长上同时记录的一系列定时单色干涉条纹,可直接确定薄膜厚度的变化。根据薄膜厚度曲线,确定了不同气泡大小和倾斜角度下给定时间的剪应力图。结果表明,气泡在倾斜表面上滑动时,TLF 的薄膜厚度在 300-1200 nm 之间,具体取决于气泡大小和倾斜角度。气泡在厚度为几百纳米的薄间隙上倾斜板上滑动时产生的剪应力约为 10-50 Pa。较大的气泡尺寸和较高的倾斜角度都会产生较高的剪切应力。实验结果与使用雷诺润滑理论得出的数值结果进行了定量比较。两个结果非常吻合。数值结果表明,倾斜板上的最大剪切应力出现在 25° 倾斜角处。这是首次实现了气泡在倾斜表面上滑动时 TLF 的时空演变,并直接确定了倾斜表面上施加的剪应力。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

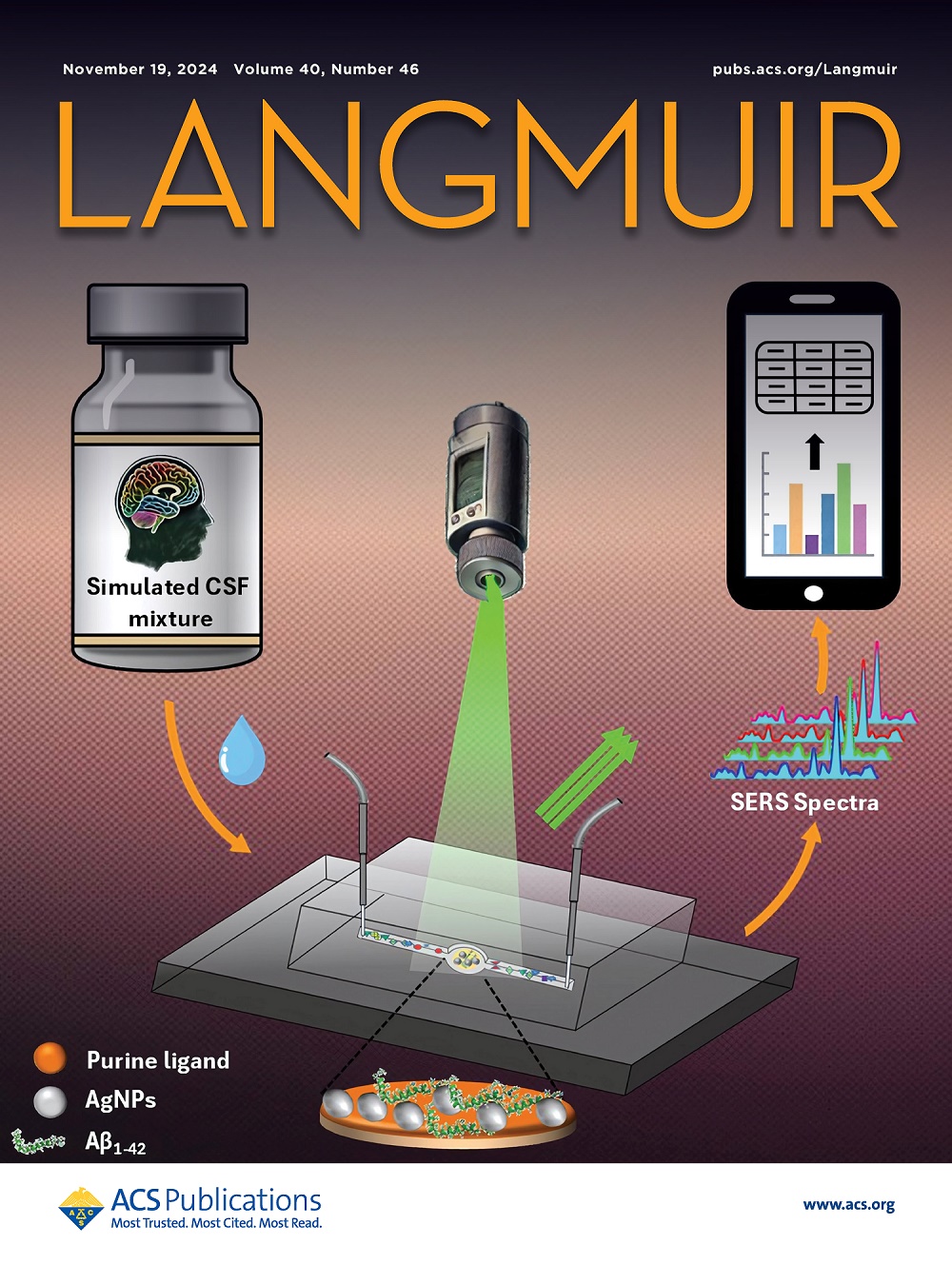

Langmuir

化学-材料科学:综合

CiteScore

6.50

自引率

10.30%

发文量

1464

审稿时长

2.1 months

期刊介绍:

Langmuir is an interdisciplinary journal publishing articles in the following subject categories:

Colloids: surfactants and self-assembly, dispersions, emulsions, foams

Interfaces: adsorption, reactions, films, forces

Biological Interfaces: biocolloids, biomolecular and biomimetic materials

Materials: nano- and mesostructured materials, polymers, gels, liquid crystals

Electrochemistry: interfacial charge transfer, charge transport, electrocatalysis, electrokinetic phenomena, bioelectrochemistry

Devices and Applications: sensors, fluidics, patterning, catalysis, photonic crystals

However, when high-impact, original work is submitted that does not fit within the above categories, decisions to accept or decline such papers will be based on one criteria: What Would Irving Do?

Langmuir ranks #2 in citations out of 136 journals in the category of Physical Chemistry with 113,157 total citations. The journal received an Impact Factor of 4.384*.

This journal is also indexed in the categories of Materials Science (ranked #1) and Multidisciplinary Chemistry (ranked #5).

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: