Cross-Linked Polyolefins: Opportunities for Fostering Circularity Throughout the Materials Lifecycle

IF 4.7

2区 化学

Q2 MATERIALS SCIENCE, MULTIDISCIPLINARY

引用次数: 0

Abstract

Cross-linked polyolefins (XLPOs) constitute a significant portion of the plastics commercial market, with a market size of a similar order of magnitude to those of polystyrene and polyethylene terephthalate. However, few aspects of XLPO materials circularity have been examined relative to thermoplastic polyolefins. The cross-linking of polyolefins imparts superior performance properties, such as impact strength, chemical and electrical resistance, and thermal stability vs thermoplastic analogues, but it also makes the reprocessing of XLPOs to valuable products more challenging, as XLPOs cannot be molten. Thus, most XLPOs are incinerated or landfilled at the end of the first lifecycle, even though XLPO products are commonly collected as a relatively clean waste stream–providing a unique opportunity for valorization. In this review, we discuss approaches to improve XLPO circularity throughout the entire materials lifecycle by examining biobased feedstocks as alternative olefinic monomer sources and by assessing both traditional mechanical and advanced XLPO recycling methods based on industrial feasibility and potential product value. We also consider how advancing materials longevity can reduce environmental impacts and lifecycle costs and how recyclable-by-design strategies can enable better end-of-life opportunities for future generations of XLPO materials. Throughout this review, we highlight XLPO circularity routes that have the potential to balance the performance, circularity, and scalability necessary to impart economic and environmental viability at an industrial scale.

交联聚烯烃:在整个材料生命周期促进循环的机遇

交联聚烯烃(XLPO)占塑料商业市场的很大一部分,其市场规模与聚苯乙烯和聚对苯二甲酸乙二酯类似。然而,与热塑性聚烯烃相比,人们对 XLPO 材料循环性的研究还很少。聚烯烃的交联赋予了其优越的性能,如冲击强度、耐化学性和耐电性以及热稳定性等,但由于 XLPO 无法熔融,因此将其再加工成有价值的产品更具挑战性。因此,大多数 XLPO 在第一个生命周期结束时都会被焚烧或填埋,尽管 XLPO 产品通常作为相对清洁的废物流被收集起来--这为价值化提供了一个独特的机会。在本综述中,我们讨论了在整个材料生命周期中提高 XLPO 循环性的方法,包括研究作为替代烯烃单体来源的生物基原料,以及根据工业可行性和潜在产品价值评估传统机械和先进的 XLPO 回收方法。我们还考虑了提高材料寿命如何减少对环境的影响和生命周期成本,以及可回收设计战略如何为下一代 XLPO 材料提供更好的生命周期终结机会。在本综述中,我们重点介绍了有可能在性能、循环性和可扩展性之间取得平衡的 XLPO 循环途径,这些途径是在工业规模上实现经济和环境可行性所必需的。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

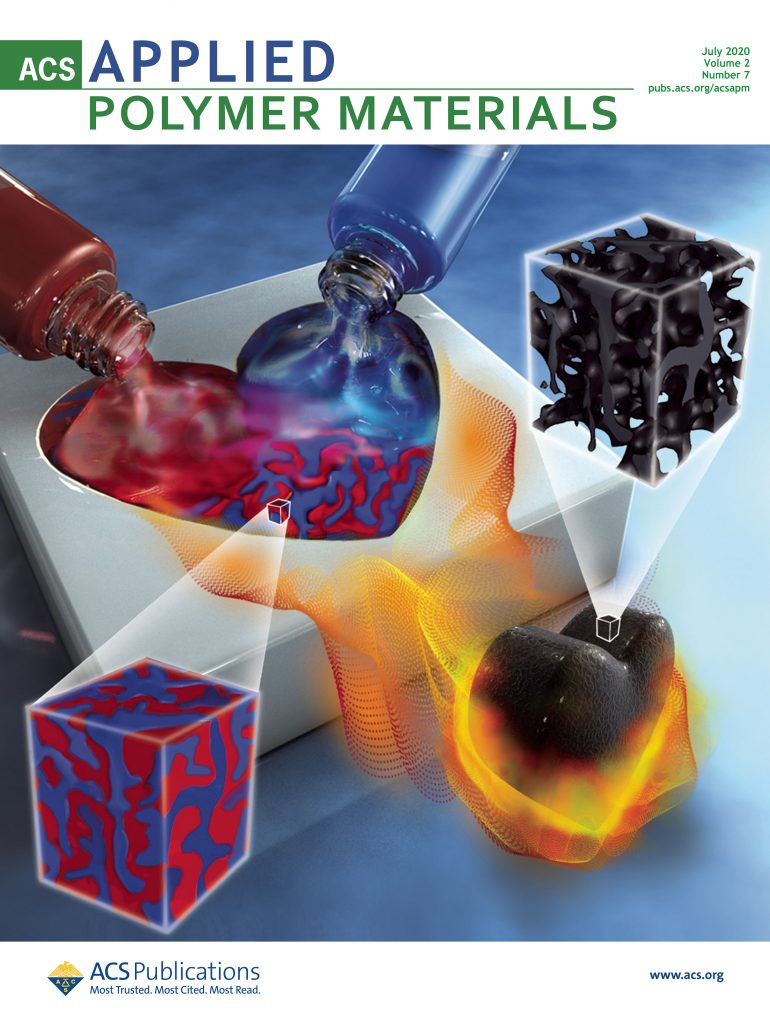

来源期刊

ACS Applied Polymer Materials

Multiple-

CiteScore

7.20

自引率

6.00%

发文量

810

期刊介绍:

ACS Applied Polymer Materials is an interdisciplinary journal publishing original research covering all aspects of engineering, chemistry, physics, and biology relevant to applications of polymers.

The journal is devoted to reports of new and original experimental and theoretical research of an applied nature that integrates fundamental knowledge in the areas of materials, engineering, physics, bioscience, polymer science and chemistry into important polymer applications. The journal is specifically interested in work that addresses relationships among structure, processing, morphology, chemistry, properties, and function as well as work that provide insights into mechanisms critical to the performance of the polymer for applications.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: