Effect of densification process on mechanical enhancement of graphene laminates

IF 17.9

2区 材料科学

Q1 Engineering

引用次数: 0

Abstract

Graphene nanosheets have attracted great attention in the field of nanotechnology applications due to their extraordinary mechanical properties. While the structural defects such as gaps will occur during the preparation of graphene laminates, which will greatly damage the performance of the macroscopic material. Hence, a simple and promising mechanical compression method is used to improve the mechanical properties of graphene laminates. However, the roles of the densification process in the mechanical enhancement mechanism of graphene laminates are not clear. In our work, the mechanical enhancement of the compressed graphene (PG) laminates was investigated by the coarse-grained molecular dynamics simulation method. The tensile strength of PG model could be increased by increasing the graphene nanosheet size and the degree of compression in the system. And the model has the stronger van der Waals effect between graphene sheets due to the larger graphene size as well as the higher overlap ratio. Furthermore, two kinds of PG laminates were prepared by densification method, and the tensile strength was consistent with the upward trend of the PG model. This work provides an in-depth understanding on the mechanical enhancement of the densification process and lays a foundation for the future practical application of graphene laminates.

致密化工艺对石墨烯层压板机械性能提升的影响

石墨烯纳米片以其优异的力学性能在纳米技术应用领域备受关注。而石墨烯层压板在制备过程中会出现缝隙等结构缺陷,对宏观材料的性能造成极大的损害。因此,采用一种简单而有前途的机械压缩方法来改善石墨烯层压板的力学性能。然而,致密化过程在石墨烯层压板力学增强机制中的作用尚不清楚。在我们的工作中,采用粗粒度分子动力学模拟方法研究压缩石墨烯(PG)层压板的力学增强。通过增加石墨烯纳米片的尺寸和系统中的压缩程度,可以提高PG模型的抗拉强度。由于石墨烯尺寸更大,重叠比更高,该模型具有更强的石墨烯片间范德华效应。通过致密化法制备了两种PG层合板,拉伸强度与PG模型的上升趋势一致。本工作对致密化过程的机械增强有了深入的认识,为石墨烯层压板的未来实际应用奠定了基础。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

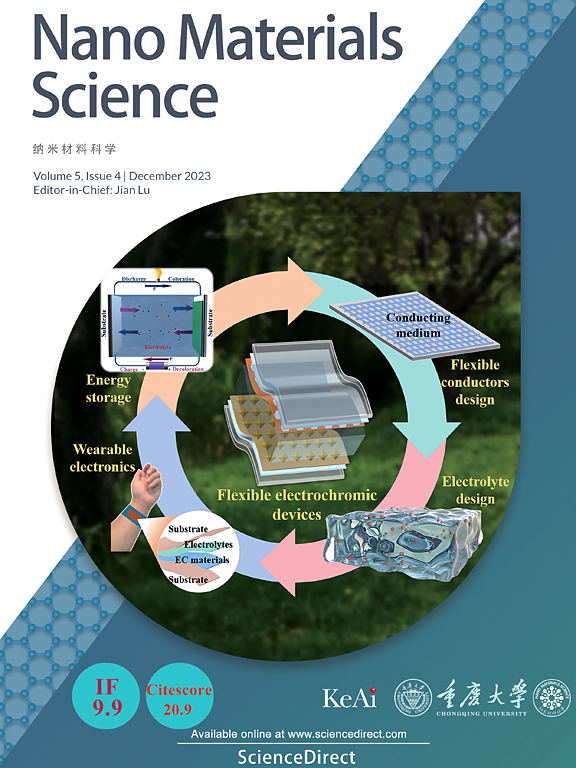

Nano Materials Science

Engineering-Mechanics of Materials

CiteScore

20.90

自引率

3.00%

发文量

294

审稿时长

9 weeks

期刊介绍:

Nano Materials Science (NMS) is an international and interdisciplinary, open access, scholarly journal. NMS publishes peer-reviewed original articles and reviews on nanoscale material science and nanometer devices, with topics encompassing preparation and processing; high-throughput characterization; material performance evaluation and application of material characteristics such as the microstructure and properties of one-dimensional, two-dimensional, and three-dimensional nanostructured and nanofunctional materials; design, preparation, and processing techniques; and performance evaluation technology and nanometer device applications.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: