Ocean-grown生物塑料

IF 41.7

1区 生物学

Q1 BIOTECHNOLOGY & APPLIED MICROBIOLOGY

引用次数: 0

摘要

Uluu的联合创始人Julia Reisser研究塑料污染,并正在寻找化石燃料塑料的替代品,她知道PHA聚合物可以通过微生物发酵产生。如何喂养这些微生物是下一个关键步骤:到目前为止,生物塑料是通过喂养土地作物或废物来创造的。相反,这位海洋学家认为富含糖的海藻可以吸收二氧化碳,是最佳的食物来源。“海藻是可扩展的、负担得起的、负碳的。[你可以]将[它]转化成pha,它可以取代大部分,如果不是全部,塑料,同时保持与环境的生物相容性,”Reisser说。Uluu的科学家们从发酵罐中提取pha,方法是用淡水将喜盐的微生物炸开。一旦PHA被制成颗粒,它们就可以被塑造成薄膜、硬质塑料或纤维来代替尼龙。这些生物塑料可以在四周内分解,即使是家庭堆肥。本文章由计算机程序翻译,如有差异,请以英文原文为准。

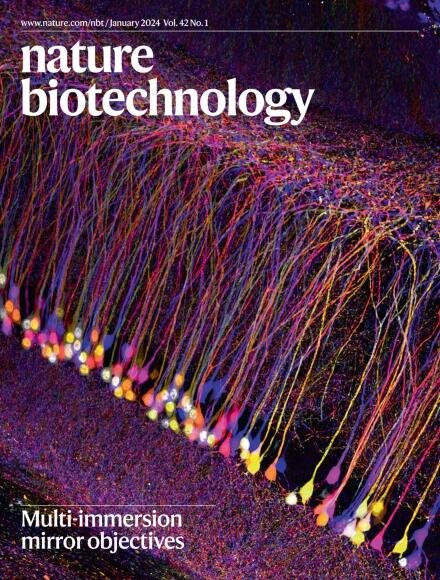

Ocean-grown bioplastics

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

Nature biotechnology

工程技术-生物工程与应用微生物

CiteScore

63.00

自引率

1.70%

发文量

382

审稿时长

3 months

期刊介绍:

Nature Biotechnology is a monthly journal that focuses on the science and business of biotechnology. It covers a wide range of topics including technology/methodology advancements in the biological, biomedical, agricultural, and environmental sciences. The journal also explores the commercial, political, ethical, legal, and societal aspects of this research.

The journal serves researchers by providing peer-reviewed research papers in the field of biotechnology. It also serves the business community by delivering news about research developments. This approach ensures that both the scientific and business communities are well-informed and able to stay up-to-date on the latest advancements and opportunities in the field.

Some key areas of interest in which the journal actively seeks research papers include molecular engineering of nucleic acids and proteins, molecular therapy, large-scale biology, computational biology, regenerative medicine, imaging technology, analytical biotechnology, applied immunology, food and agricultural biotechnology, and environmental biotechnology.

In summary, Nature Biotechnology is a comprehensive journal that covers both the scientific and business aspects of biotechnology. It strives to provide researchers with valuable research papers and news while also delivering important scientific advancements to the business community.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: