CeO2 和微米级铜的协同效应可促进 CO2 加氢转化为 CO

IF 2.8

4区 工程技术

Q2 ENGINEERING, CHEMICAL

引用次数: 0

摘要

由于微米铜粉粒径大、比表面积小,其催化应用受到限制。对微米铜粉进行改性以获得高催化性能是微米铜应用中的一项挑战。本研究利用微铜合成了 CeO2-Cu 催化剂,并利用 XRD、BET 等分析了其相组成和表面孔结构。我们将 CeO2-Cu 催化剂与 CeO2 和 Cu 的 CO2 加氢性能进行了对比分析,发现 CeO2-Cu 催化剂在 Cu 和铈之间表现出协同效应,使其在 500 °C 时的加氢性能远高于单独使用 CeO2 或 Cu 时的加氢性能。H2-TPR 和 TEM 表征显示,CeO2-Cu 催化剂与相对较大的 Ce-Cu 界面形成了界面相互作用,其中氧化铈可促进 CuO 的还原并降低还原温度。此外,氧化铈形成了对 Cu 的约束结构,CeO2-Cu 催化剂表现出更高的氧空位浓度,从而提高了 CO2 加氢性能。Cu-CeO2 的相互作用为微米级 Cu 粉末的催化应用提供了宝贵的见解。本文章由计算机程序翻译,如有差异,请以英文原文为准。

The Synergistic Effect of CeO2 and Micron-Cu Enhances the Hydrogenation of CO2 to CO

The catalytic applications of micron Cu powder are limited due to its large particle size and small specific surface area. Modifying micro-Cu powder to achieve a high catalytic performance is a challenge in the application of micron copper. In this work, micro-Cu was used to synthesize a CeO2–Cu catalyst, and the phase composition and surface pore structure were analyzed using XRD, BET, etc. The CO2 hydrogenation performance of the CeO2–Cu catalyst was analyzed in comparison with CeO2 and Cu, and we found that the CeO2–Cu catalyst exhibited a synergistic effect between Cu and cerium, resulting in a much higher hydrogenation performance at 500 °C than CeO2 or Cu alone. H2-TPR and TEM characterization revealed that the CeO2–Cu catalyst formed interfacial interactions with a relatively large Ce–Cu interface, where cerium oxide could promote the reduction of CuO and lower the reduction temperature. Additionally, cerium oxide formed a confinement structure for Cu, and the CeO2–Cu catalyst exhibited a higher oxygen vacancy concentration, thereby promoting the CO2 hydrogenation performance. Cu–CeO2 interaction provides valuable insights into the catalytic application of micron Cu powder.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

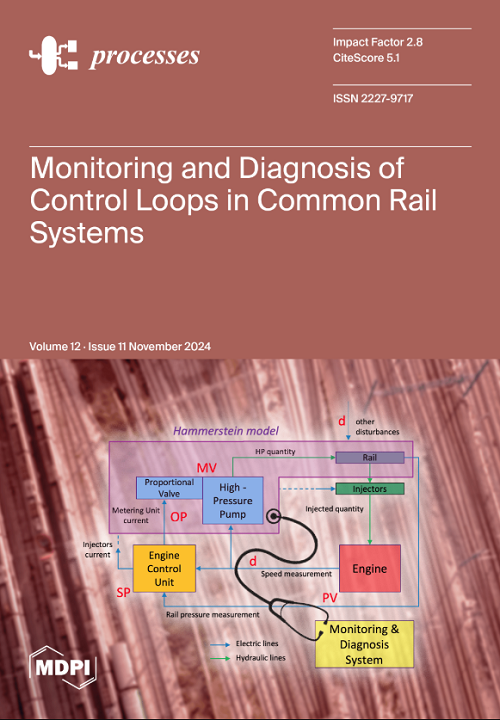

Processes

Chemical Engineering-Bioengineering

CiteScore

5.10

自引率

11.40%

发文量

2239

审稿时长

14.11 days

期刊介绍:

Processes (ISSN 2227-9717) provides an advanced forum for process related research in chemistry, biology and allied engineering fields. The journal publishes regular research papers, communications, letters, short notes and reviews. Our aim is to encourage researchers to publish their experimental, theoretical and computational results in as much detail as necessary. There is no restriction on paper length or number of figures and tables.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: