通过集成激光后处理的机器人铸造技术快速制造质子传导陶瓷

IF 6.9

2区 材料科学

Q1 MATERIALS SCIENCE, MULTIDISCIPLINARY

引用次数: 0

摘要

我们设计了一种结合了机械铸造和近红外激光后处理的混合系统,用于制造混合质子电子导电钴铁氧体陶瓷层。所提出的制造技术可以控制几何形状和微观结构,并将制造时间缩短到几分钟。使用 5 W 激光功率和 500 mm-s 的扫描速度,在不到 2 秒的时间内就烧结了半径为 8 mm 的圆形层。对不同的陶瓷-聚合物重量比进行了测试,结果表明,在 2:1 和 4:1 的负载条件下,可分别获得 ∼30 - 35 % 和 ∼19 % 的微结构孔隙率。本文章由计算机程序翻译,如有差异,请以英文原文为准。

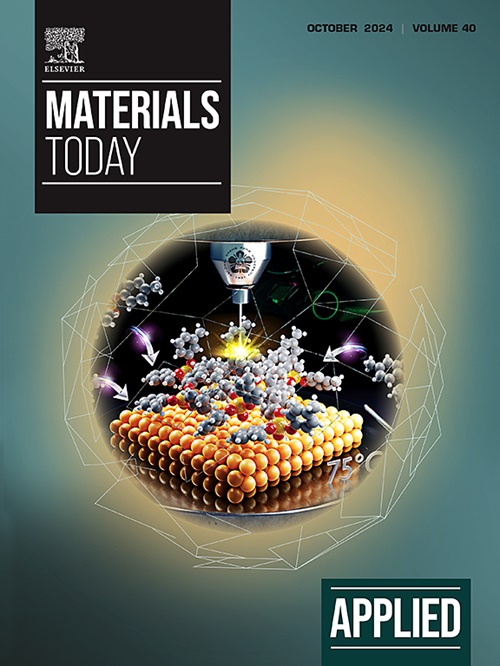

Additive manufacturing of Proton-Conducting Ceramics by robocasting with integrated laser postprocessing

A hybrid system combining robocasting and NIR laser postprocessing has been designed to fabricate layers of mixed proton-electron conducting BaLaCoFeO ceramic. The proposed manufacturing technique allows for the control of the geometry and microstructure and shortens the fabrication time to a range of a few minutes. Using 5 W laser power and a scanning speed of 500 mm·s, sintering of a round-shaped layer with an 8 mm radius was performed in less than 2 s. The single phase of the final product was confirmed by X-ray diffraction. Various ceramic-to-polymer weight ratios were tested, showing that various porosities of microstructures of ∼30 - 35 % and ∼19 % can be obtained with 2:1 and 4:1 loading respectively.

求助全文

通过发布文献求助,成功后即可免费获取论文全文。

去求助

来源期刊

Applied Materials Today

Materials Science-General Materials Science

CiteScore

14.90

自引率

3.60%

发文量

393

审稿时长

26 days

期刊介绍:

Journal Name: Applied Materials Today

Focus:

Multi-disciplinary, rapid-publication journal

Focused on cutting-edge applications of novel materials

Overview:

New materials discoveries have led to exciting fundamental breakthroughs.

Materials research is now moving towards the translation of these scientific properties and principles.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: