Nanoscale Core–Shell Catalysts for H2 Production by Methane Decomposition: Supported Nickel Nanoparticles Ensheathed in Metal Oxides

IF 15.6

1区 化学

Q1 CHEMISTRY, MULTIDISCIPLINARY

引用次数: 0

Abstract

Catalytic methane decomposition provides a potentially viable route to low-cost, COx-free H2 from this abundant source. A remaining challenge is to facilitate the needed low-temperature C–H bond activation with high catalytic activity and stability. We now report the design and synthesis of supported Ni catalysts that address these limitations; they consist of silica-supported Ni nanoparticles ensheathed in nanoscale TiO2 shells, forming an embedded core–shell structure that provides catalyst stability, maintaining a H2 site-time yield of 3.6 mol/gNi/h at a space velocity of 24000 mL gcat–1·h–1 at 550 °C for 6 h on stream in a flow reactor. In contrast, a comparable catalyst without the sheath deactivated after only 2.5 h, being characterized by a Ni-extracting tip-growth mechanism of coproduct carbon nanotube formation that destroyed the catalyst. An advantage of the ensheathed catalyst is that it facilitates a Ni-sparing base-growth mechanism. Infrared and Raman spectra, combined with other catalyst characterization data and calculations at the level of density functional theory, show that the TiO2 sheaths barely hinder the C–H bond cleavage and carbon nanotube formation on the underlying nickel, while providing the advantages stated above. We postulate that these results provide guidance for the synthesis of catalysts for low-temperature H2 production and related reactions requiring C–H bond activation.

甲烷分解制氢的纳米核壳催化剂:金属氧化物包裹的负载镍纳米颗粒

催化甲烷分解为从这种丰富的资源中获得低成本、无cox的氢气提供了一条潜在的可行途径。剩下的挑战是促进所需的低温C-H键活化,具有高催化活性和稳定性。我们现在报告了负载型镍催化剂的设计和合成,以解决这些限制;它们由二氧化硅负载的Ni纳米颗粒包裹在纳米级TiO2壳层中,形成嵌入核壳结构,提供了催化剂的稳定性,在550°C的流动反应器中,在24000 mL gcat-1·h - 1的空速下,在6 h的流动反应器中保持了3.6 mol/gNi/h的H2位点时间产率。相比之下,没有护套的类似催化剂仅在2.5 h后就失活了,其特征是副产物碳纳米管形成的镍提取尖端生长机制破坏了催化剂。包覆催化剂的一个优点是它有利于镍节约碱的生长机制。红外和拉曼光谱,结合其他催化剂表征数据和密度泛函理论水平的计算,表明TiO2护套几乎不阻碍其下面的镍上的C-H键裂解和碳纳米管的形成,同时具有上述优点。我们假设这些结果对低温制氢催化剂的合成以及需要激活C-H键的相关反应具有指导意义。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

CiteScore

24.40

自引率

6.00%

发文量

2398

审稿时长

1.6 months

期刊介绍:

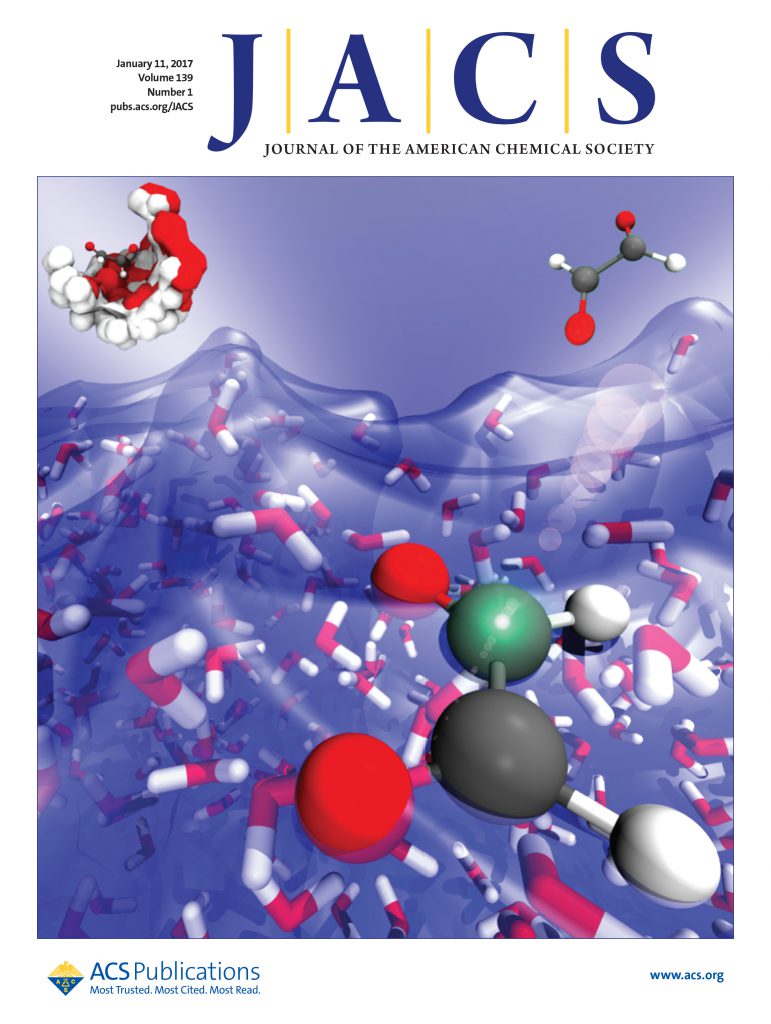

The flagship journal of the American Chemical Society, known as the Journal of the American Chemical Society (JACS), has been a prestigious publication since its establishment in 1879. It holds a preeminent position in the field of chemistry and related interdisciplinary sciences. JACS is committed to disseminating cutting-edge research papers, covering a wide range of topics, and encompasses approximately 19,000 pages of Articles, Communications, and Perspectives annually. With a weekly publication frequency, JACS plays a vital role in advancing the field of chemistry by providing essential research.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: