Achieving superior high-temperature strength in an additively manufactured high-entropy alloy by controlled heat treatment

IF 6.9

2区 材料科学

Q1 MATERIALS SCIENCE, MULTIDISCIPLINARY

引用次数: 0

Abstract

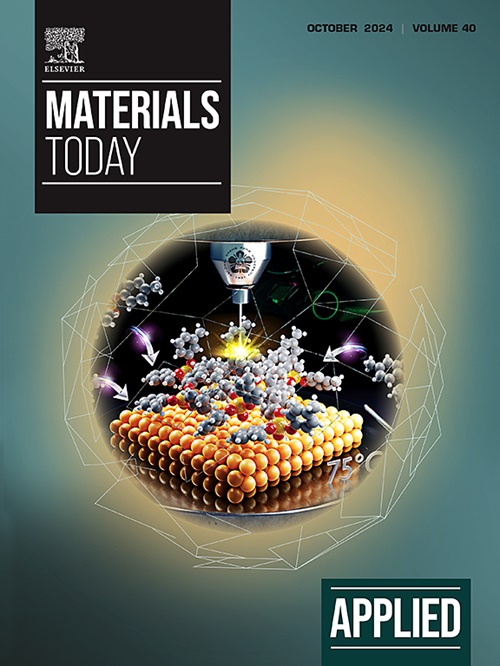

High-entropy alloys (HEAs) usually exhibit high strengths at ambient and low temperatures but rapidly degraded tensile properties with increased temperature. In this study, a high-strength HEA, (CoCrNi)(TiAl), is selected and subjected to laser powder bed fusion (L-PBF) and ageing treatment. The microstructural evolution and mechanical property development of the material over a wide range of temperatures are thoroughly investigated. It is found that the as-printed microstructure is dominated by numerous ultrafine cellular structures (∼1 μm) with cell boundaries decorated by AlO nanoparticles, leading to high 0.2% yield strength (YS = 725∼750 MPa) and excellent elongation (>28%) at room temperature. The cellular structures remain up to 700 °C but disappear at or above 800 °C. Ageing at or above 600 °C leads to significant γ′ precipitation with the particle size increasing constantly with increased temperature. The samples containing both cellular structures and coarsened γ′ precipitates (aged at 700 °C) exhibit the highest YS (∼1227 MPa) and ultimate tensile strength (UTS∼1539 MPa) at room temperature and display unprecedented YS at high temperatures, i.e., 949 MPa at 600 °C and 728 MPa at 700 °C, respectively. The exceptional tensile strengths are mainly due to the γ′ precipitates and cell boundaries decorated by AlO nanoparticles which may have acted as strong barriers for dislocation motion. At room temperature, the sample deforms mainly by dislocation slip and formation of stacking faults while at elevated temperatures, deformation becomes increasingly planar as characterized by the formation of increased number of stacking faults and the activation of twinning.通过控制热处理实现添加式制造高熵合金的超强高温强度

高熵合金(HEA)通常在常温和低温下具有较高的强度,但随着温度的升高,其拉伸性能会迅速下降。本研究选择了一种高强度 HEA (CoCrNi)(TiAl),并对其进行了激光粉末床熔化 (L-PBF) 和时效处理。对该材料在宽温度范围内的微观结构演变和机械性能发展进行了深入研究。研究发现,印刷后的微观结构以大量超细蜂窝结构(1 ∼ 1 μm)为主,蜂窝边界由 AlO 纳米颗粒装饰,因此在室温下具有较高的 0.2% 屈服强度(YS = 725 ∼ 750 MPa)和出色的伸长率(>28%)。蜂窝结构在 700 °C 时仍然存在,但在 800 °C 或以上时消失。在 600 °C 或以上的温度下老化会导致γ′大量析出,粒径随温度升高而不断增大。同时含有蜂窝结构和粗化γ′沉淀物的样品(在 700 ℃ 下老化)在室温下表现出最高的 YS(1227 兆帕)和极限抗拉强度(UTS∼1539 兆帕),并在高温下表现出前所未有的 YS,即 600 ℃ 时为 949 兆帕,700 ℃ 时为 728 兆帕。优异的拉伸强度主要归功于 AlO 纳米粒子装饰的 γ′ 沉淀和晶胞边界,它们可能成为位错运动的强大屏障。在室温下,样品主要通过位错滑移和堆积断层的形成发生变形,而在高温下,变形变得越来越平面化,堆积断层的形成数量增加,孪晶被激活。

本文章由计算机程序翻译,如有差异,请以英文原文为准。

求助全文

约1分钟内获得全文

求助全文

来源期刊

Applied Materials Today

Materials Science-General Materials Science

CiteScore

14.90

自引率

3.60%

发文量

393

审稿时长

26 days

期刊介绍:

Journal Name: Applied Materials Today

Focus:

Multi-disciplinary, rapid-publication journal

Focused on cutting-edge applications of novel materials

Overview:

New materials discoveries have led to exciting fundamental breakthroughs.

Materials research is now moving towards the translation of these scientific properties and principles.

求助内容:

求助内容: 应助结果提醒方式:

应助结果提醒方式: